Research » Aluminum Recycling and Melt Purification

Title

Type

Sponsorship

Duration

Partner

Research Area

Description

Approximately 21% of global greenhouse gas (GHG) emissions are caused by the industrial sector. Increasing concern about global climate change is leading many industries to pursue projects to reduce their “carbon footprint” in order to reduce their impact on the changing climate. Zero CO2 emissions in primary production is therefore the goal for the global aluminium industry. The aluminium industry has been working for decades to develop a CO2-free manufacturing process by replacing the horizontal carbon anodes in Hall-Héroult’s electrolysis cells operating at 960°C with inert non-carbon anodes, but without achieving any technical or commercial success, mainly due to material problems at this high operating temperature, impurities in the metal produced and increased energy consumption.

Title

Type

Sponsorship

Duration

Partner

Research Area

Description

It is the goal to minimize the primary energy consumption and maximise metal yield by prozess optimization of combined thermal pre-treatment and melting of organic contaminated aluminium scrap. This is to be achieved by efficiently using the thermolysis gases of thermal pre-treatment, which has not been achieved by industrial processes, yet. The process optimisation is based on the fundamental investigation of a microwave rotary furnace for thermolysis of aluminium scrap, the development of a process control system for thermolysis gas combustion and the technical comparison of three industrial melting processes. With this process development and the generated data set, the transfer into pilot scale is possible after the project. The data set will be available for equipment manufacturers and industrial users, enabling industrial application and market-driven distribution.

Title

Type

Sponsorship

Duration

Partner

Research Area

Description

Since no research center or company worldwide pursues this goal or develops or operates a similar process, the innovation potential of this process idea is obvious. The innovation, but at the same time the challenge here, is to maintain and even improve the necessary chemical-physical properties of the salt mixtures as the KCl content of the salt mixture is lowered. If this path leads to success, a reduction in production costs can be measured immediately.

Title

Type

Sponsorship

Duration

Research Area

Description

-

In metal winning and recycling processes like for Magnesium, Aluminium, even Copper or Zink molten salt fluxes , mostly containing KCl, NaCl and CaF2 are used. They have the role of separation of surface oxides, gases or other contaminations from metal as well as isolating the metal phase from the atmosphere. It is state of the art that application of salt flux in contact with contaminated raw materials like scrap leads inevitably to the formation of a salt-oxide-metal suspension, containing the both metallic and oxidized metal as well as salt components. Up to now it has not been yet possible to control this sludge formation in respect to metal losses and process feasibility.

Title

Type

Sponsorship

Duration

Partner

Research Area

Description

The project aim is the detailed material balance and recording as well as evaluation of the melting metallurgy for foundries in crucible induction furnaces and in format casting foundries in induction furnaces and multi-chamber furnaces with Vortex and EMP for the recycling of internal aluminium machining chips. In addition, a distinction is made to other melting aggregates in which the aluminium cycle is recycled.

Title

Type

Sponsorship

Duration

Partner

Research Area

Description

The primary aim is to achieve a cost saving potential by shortening the process chain and increasing the salt and aluminium yield of the overall process. From a scientific-technical point of view, the project represents the development and testing of a process with the aid of published laboratory results for various individual process steps. The research project is aimed at the development of a process for the direct or integrated recycling of salt slag in the molten state and the recycling of the metal and salt contents of the salt slag in liquid form into the cycle as well as their testing of the process on a pilot scale.

Title

Type

Sponsorship

Duration

Partner

Research Area

Description

-

The aim of the project is to demonstrate a crystallization process for the purification of ferrous multi-component Al casting alloys from Fe, Mn, Mg, Ti by intermetallic precipitation. In particular, the interaction with the alloying element silicon will be investigated.

Title

Type

Sponsorship

Duration

Partner

Research Area

Description

-

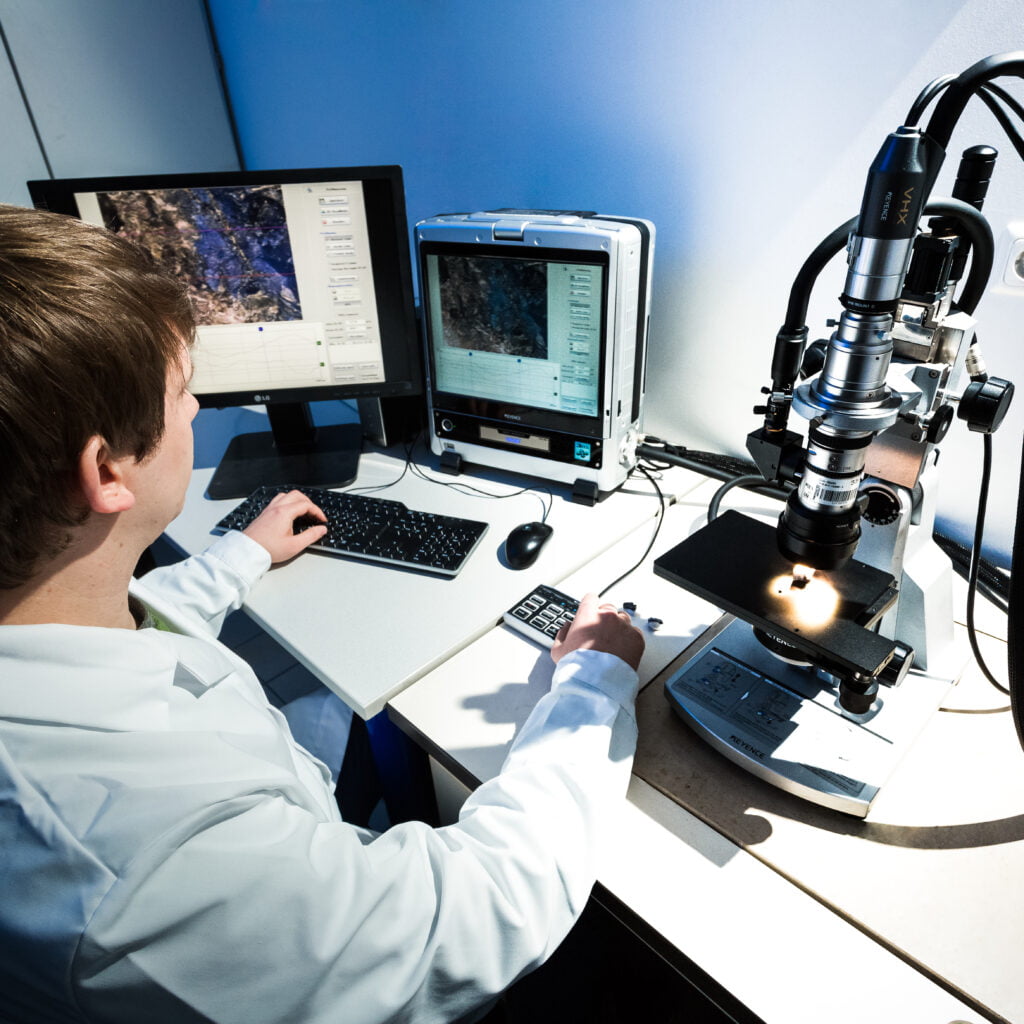

In aluminium production Fe, Si and Mn are common sources of contamination. It is possible to remove these contaminations by the active formation and subsequent removal of inter-metallics. To make this process economical the inter-metallic formation should be optimized by the addition of extra trace elements. A systematic experimental search program will be carried out to find the economically optimal additives. The subsequent removal stage requires very accurate temperature control and the development of an advanced aluminium filtration technology such as displacement washing. These developments will be undertaken at lab-scale, and then scaled-up. The final result of the project will be a semi-continuous in-line filtration module for the removal of Fe, Si and Mn at a cost of less than 200 USD/t. The technology will be applicable in a typical aluminium casthouse, for instance between the melting and casting furnace.

Title

Type

Sponsorship

Duration

Partner

Research Area

Description

The melting of heavily contaminated or finely divided scrap often takes place under a salt bath, which usually consists of NaCl, KCl and fluoride salt additives. In Germany, smelting salts based on a salt mixture of approx. 70 % NaCl and approx. 30 % KCl are most frequently used. The used fluoride salts are mostly CaF2 and rarely cryolite. There are few investigations which refer to this base salt mixture. Therefore, the properties of the melting salt and their influence on the melt yield when melting aluminium scrap were investigated in this paper. In the literature, the basic properties of the melting salt, such as density and surface tension as a function of temperature, CaF2- and Na3AlF6- concentration, are not available. To fill this gap, they were measured in this thesis.

Title

Type

Sponsorship

Duration

Partner

Research Area

Description

The aim of the current project is the development of a melting method for finely divided aluminium residues, which ensures a high yield of aluminium as well as minimising the amount of salt slag. The new process is based on the continuous melting of fine-particle Al precursors under large excess salt (ideal conditions) and on the simultaneous separation of the oxides from the molten salt slag by means of an immersion centrifuge. Instead of a liquid salt slag, a residual filter mass with oxide contents of up to 60 % is produced. This reduces the need for salt and the amount of salt slag. Furthermore, a much more liquid salt bath (hardly any oxide content) keeps fewer Al droplets in suspension, which drastically reduces metal losses. Since filter residues or conventional salt slags are generally leached during processing under conditions in which metallic Al oxidizes, power losses can be minimized.

Title

Type

Sponsorship

Duration

Partner

Research Area

Description

The overall objective of the project is the development of recycling concepts for the processing and utilisation of scrap from special aluminium materials (aluminium foams, Al-Fe and Al-Mg composite materials and the cleaning of Al melts from Pb, Sn, Sb, Li and Cd). Due to their content of alloying elements or built-in parts, these cannot currently be incorporated into the existing recycling concepts of the aluminium cycle, as they can have a negative effect on the quality of the secondary alloys. The results of the research and development work will be made available to the industry, in particular to the German-based recyclers of aluminium scrap (smelters, remelters), following a positive course of the project.