Research » Circular Economy for Batteries

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

The EarLi project adress the sustainable recycling of lithium from used lithium-ion batteries from the battery cell production funding call. Worldwide, neither industrial or semi-industrial processes nor scientific approaches can be validated that can economically recover this critical raw material in high quality. The loss of value added is increasing dynamically with the rapidly growing amount of waste, and the new European battery legislation will make lithium recovery and recyclate use mandatory from 2026. The project partners are developing and installing an innovative process chain on an industrial scale, in which the lithium in end-of-life battery cells is first transformed into water-soluble lithium compounds using energy-neutral thermolysis. This transformation enables the earliest possible extraction of lithium from the black mass by aqueous neutral leaching, thus preventing dissipative dispersion in the subsequent extractive metallurgical treatment steps of the black mass. A new type of electrolytic membrane filtration then separates the lithium hydroxide monohydrate, which is preferred by precursor manufacturers, from the solution in high quality. The EarLi process chain, which has been tried and tested on lab scale, is particularly characterized by the complete elimination of chemicals, low resource requirements due to the water cycle and low energy consumption due to the energy-neutral thermal pretreatment. This high level of development is the prerequisite for sustainably changing the entire value chain in battery recycling. For the first time, a salable lithium product with a low ecological footprint can be recovered in Europe under competitive cost conditions.

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

Das Projekt „HVBatCycle“ hat das übergeordnete Ziel, innovative, nachhaltige und energieeffiziente Prozesse entlang der Wertschöpfungskette von Hochvoltbatterien aus Elektrofahrzeugen zu entwickeln und tiefergehend zu verstehen, um in naher Zukunft die geschlossene Kreislaufführung von Batteriematerialien zu ermöglichen. Insbesondere sollen die Prozesse zur sortenreinen Demontage, zum ökologisch effizienten Recycling von End-of-Life Batterien sowie zur Herstellung neuer Batteriematerialien aus den zurückgewonnen Sekundärrohstoffen untersucht und deren Skalierbarkeit sowie Wirtschaftlichkeit aufgezeigt werden. Aufbauend auf unterschiedlichsten Vorgängerprojekten bei den teilnehmenden Partnern sollen Neu- und Weiterentwicklungen dargestellt werden, wie und mit welchem finanziellen sowie technischen Aufwand die Anforderungen der neuen EU-Gesetzgebung hinsichtlich des stofflichen Recyclings von Li-Ionen Batterien bis zum Jahr 2030 erreicht und sogar übertroffen werden können. Durch ein interdisziplinär aufgestelltes und hochqualifiziertes Konsortium sollen auf zahlreichen Kerngebieten der Partner innovative Prozesse einer verketteten End-to-End Wertschöpfungskette entwickelt, untersucht und, mit Ausnahme der Elektrolytaufbereitung, aus dem Labor in eine prototypische Umsetzung auf mind. TRL6 geführt werden. Ergänzend wird geprüft, ob die hergestellten Sekundärmaterialien auch für einen erneuten Einsatz in der Batteriezelle im Sinne der mehrfachen Kreislaufführung geeignet sind. Zudem wird, dem Recyclingprozess vorgeschaltet, eine Batterieanalyse durchgeführt, die vorab die eingehenden Batterien hinsichtlich einer möglichen Weiternutzung im 2nd Life vorsortiert.

IME project management: Dominik Schmitz

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

Mit der Aufnahme von Lithium in die Liste der kritischen Rohstoffe räumt die Europäische Union dem Leichtmetall eine strategische Bedeutung in der Schlüsseltechnologie Elektromobilität ein. Das Metall wird ausschließlich importiert und belegt das Versorgungsrisiko für den Aufbau einer europäischen Zellfertigung. Gleichzeitig erfordern die exponentiell ansteigenden Altbatteriemengen innovative Verfahrenskonzepte, um Lithium energieeffizient zurückzugewinnen und eine partielle Eigenversorgung für die zukünftige Mobilitätswende unter höchsten ökologischen Ansprüchen bereit zu stellen. Die hier vorgestellte Projektskizze adressiert sowohl Ressourcen- als auch Energieeffizienz für eine umweltfreundliche Mobilität mit der Umsetzung eines labortechnisch erfolgreich vaildierten Verfahrens zur chemikalienfreien Lithiumsalzgewinnung aus Lithium-Ion basierten Altbatterien. Durch die Anwendung neuartiger Extraktions- und Raffinationsmethoden soll ein hochwertiges Lithiumsalz mit minimalem Betriebsmitteleinsatz direkt aus thermisch und mechanisch vorbehandelten gebrauchten Lithium-Ion Batterien recycelt und als Ausgangsprodukt für die Batteriezellfertigung zur Verfügung gestellt werden. Bisher sind europaweit dazu weder industrielle Verfahren verfügbar noch Pilotanlagen geplant. Mit der Revision der Batteriedirektive ist das Recycling von Lithium allerdings ab dem Jahr 2026 stufenweise verpflichtend vorgesehen. Diese Lücke soll das Projekt CLIMA durch Lithiumextraktion und anschließende Aufreinigung aus dem Stoffstrom der Altbatterien realisieren.

The project is financially supported by the European Union and the State of NRW within the framework of the programme “InnovationUmweltwirtschaft.NRW” issued by EFRE.NRW (REACT-EU).

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

Neben konventionellen, auf Flüssigelektrolyt basierenden LIB werden in den kommenden Jahren Festkörperbatterien (engl. all-solid-state batteries, ASSB) auf Basis von Festelektrolyten mit lithiumbasierten oder auch lithiumfreien Anoden auf den Markt kommen. Das Projekt S2taR adressiert die Übertragung der bereits bestehenden und im Rahmen des Recyclings & Green Battery Clusters weiterentwickelten Recyclingkonzepten für die konventionelle LIB auf zukünftige Batteriesysteme zur Evaluation und Bewertung der Übertragbarkeit der mechanischen, thermischen, pyrometallurgischen und hydrometallurgischen Recyclingstrategien um schon während der Produktionsentwicklungsphase von Produktionsprozessen und skalierbaren Materialentwicklungen ein nachhaltiges Design, d.h. Design for Recycling zu berücksichtigen.

IME project management: Emanuel Sebastian Drude

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

Im Fokus dieses Projektes steht die selektive Zerkleinerung von Batterien mittels Elektrohydraulische Zerkleinerung, dies geschieht beim Kooperationspartner IWKS. Im Vorfeld werden am IME die Batterie Zellen thermisch Vorbehandelt. Nach der Zerkleinerung am IWKS wird das Aktivmaterial wieder zum IME geschickt. Es folgt eine hydrometallurgische Aufbereitung, mit dem Fokus organische Säuren einzusetzen. Die Produkte werden für eine Resynthese von Lithiumhalbzellen an das ISC geschickt. Von den Arbeitsschritten thermische Vorbehandlung und Hydrometallurgie werden digitale Zwillinge vom HZDR angefertigt und der Prozess durch eine Lebenszyklusanalyse vom IWKS bewertet.

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

Das Projekt SIMTEGRAL im Rahmen des Clusters Recycling & Green Battery beschäftigt sich mit der Analyse und der nachhaltigen Gestaltung komplexer Wertschöpfungsketten von Rohstoffen für Li-Ion Batterien. Physikalisch basierte Modelle der wichtigsten Prozesse zur Primär- und Sekundärrohstoffherstellung werden entwickelt und experimentell validiert. Diese Modelle liefern deutlich detailliertere Prozessdatensätze als bisher verfügbar. Sämtliche Modelle werden in einen übergeordneten Ansatz für eine techno-ökonomische, soziale sowie ökobilanzielle Bewertung integriert. Angestrebt ist die Ermittlung belastbarer Kennzahlen im Kontext von Energie- und Ressourceneffizienz, Qualität (Rohstoffreinheit), Wirtschaftlichkeit (Investitionen und Betriebskosten), sozialen Risiken sowie der Umweltauswirkungen der Batterierohstoffe. Das Vorhaben trägt wesentlich zum ganzheitlichen Verständnis des Batterielebenszyklus bei und legt dabei den Fokus auf die Rohstoffrückgewinnung.

IME project management: Dominic Dittmer

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

Bislang sind Sensor- und Digitalisierungslösungen im industriellen Recyclingbetrieb jedoch allenfalls in Ansätzen und nur für Einzelprozesse vorhanden. Im Fokus des Projektes DiRectION steht daher die systematische Erfassung und Verarbeitung von Produkt- und Prozessdaten im Batterierecycling sowie deren prozessübergreifende Zusammenführung und Auswertung. Hierzu werden an bestehenden bzw. aufzubauenden Recyclinginfrastrukturen der mechanischen, den sogenannten hydro- sowie pyrometallurgischen Recyclingprozessketten, Systeme zur Datenerfassung und -verarbeitung installiert. Die Auswertung der großen Datenmengen erfolgt automatisch mithilfe des Data-Minings, also durch automatisiertes Durchsuchen und Bewerten von Datensätzen. Hierdurch kann der Einfluss verschiedener Prozessparameter auf die Ausbeute oder Reinheit rückgewonnener Rohstoffe gezielt untersucht werden.

IME project management: Wei Song, Fabian Diaz

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

Das Projekt zielt darauf ab, neue Wege für ein effizientes Recycling von Lithium-Ionen-Batterien zu erforschen und zu entwickeln, die Pyrometallurgie, Schlackenaufbereitung und Hydrometallurgie kombinieren. Der Plan enthält auch eine technoökonomische und umweltbezogene Bewertung, um die Robustheit und mögliche industrielle Anwendung der untersuchten Verarbeitungsrouten zu bestimmen. Durch Pyrometallurgie können mehrere in Batterien vorhandene Metalle wie Co, Ni, Cu, Fe und Mn durch Koagulation in eine metallische Phase zurückgewonnen werden. Das Ziel des Clusters ist es jedoch, den Einfluss von Al und Mn während des Schmelzens zu untersuchen, um die selektive Keimbildung von LiAlO2 zu verbessern und die Extraktion von Lithium durch mechanische Verarbeitung und Hydrometallurgie zu fördern. Neben der Rückgewinnung wertvoller Elemente wird voraussichtlich eine saubere Mineralphase erzeugt, die als Vorstufe für die Bauindustrie verwendet werden kann.

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

Das ecoLiga Projekt bilanziert die Nachhaltigkeit im Hinblick auf Fertigung und Recyclingfähigkeit von Kohlenstoffmaterialien und ermöglicht so ein neues und nachhaltiges Batteriedesign. Demzufolge ist eine Kernfrage des Projekts die Stoffkreisläufe von Batteriekomponenten zur Schließung und Verwendung der Kohlenstoffmaterialien auf der Grundlage eines Design for Recycling. So können die Felder Batteriefertigung und -recycling inhaltlich miteinander verknüpft werden und Kooperationswege aufgezeigt werden, um sich im Feld einer nachhaltigen Innovationsentwicklung zu bewegen. Insbesondere wird das entwickelte Vorgehen an Hand von Lithium-Schwefel Batterien als ein innovatives Batteriesystem validiert. Somit wird eine optimale Vorbehandlung mit einem geeigneten Extraktionsverfahren der Aktivmasse, die Kohlenstoffmaterialrückgewinnung, eine ganzheitliche Rohstoffrückgewinnung zur Maximierung der Ausbeute, und die Resynthese im Batteriesystem durchgeführt.

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

Complete Recycling is a basic prerequisite for closing material usage loop of Li-ion batteries and is thus of increasing importance for the economic efficiency and sustainability of such energy storage systems. Since lithium in particular is largely lost in conventional recycling processes, it should be recovered from the so-called black mass right at the beginning of the process chain. Otherwise a dissipation of Li via various material streams of the overall process can not be avoided. In the research project \”EarLiMet\”, therefore, a comprehensively resource-efficient, predominantly hydrometallurgical recycling of the valuable components in Li-ion batteries up to the TRL 5/6 level is to be developed. The concept pursued in EarLiMet aims at a zero-waste approach, which requires a complete consideration and balancing of the entire process.

IME project management: Daniel Munchen, Ksenija Milicevic Neumann

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

Mit dem Forschungsvorhaben AURRELIA wird das Ziel verfolgt, den Recyclingprozess von Post-Consumer Lithium-Ionen-Batterien (LIBs) durch die Entwicklung geeigneter Verfahren entlang der Prozesskette von der mechanischen bis zur hydrometallurgischen Aufbereitung zu optimieren. Hierbei soll ein möglichst großer Anteil der Batterie einem Recycling zugänglich gemacht werden.

Im Sinne eines Zero-Waste-Prozesses sollen hohe Ausbeuten und Reinheiten der gewonnenen Produkte erzielt werden. Zentraler Bestandteil des Vorhabens ist die recyclinggerechte und wirtschaftliche Aufbereitung der LIBs, bei der geeignete Zerkleinerungs- und Aufbereitungsverfahren untersucht werden. Mittels optimierter Schredder-Technik werden die LIBs im nassen Milieu zerkleinert, und anschließend in feste und flüssige Phasen separiert, so dass eine stoffstromspezifische Weiterbehandlung der Materialströme und damit eine umfassende Rückgewinnung der LIB-Komponenten möglich wird. Im Vordergrund steht dabei besonders die Vermeidung von Lithiumverlusten. Das Verfahren beginnt mit einem Schredder-Prozess in wässriger Umgebung, wodurch die manuelle Demontage der Batterien entfällt. Im Anschluss erfolgt eine produktorientierte Separation, um Feststoffe und flüssigen Phasen als getrennte Fraktionen zu erhalten. Die in Lösung gebrachten Bestandteile des Elektrolyten und des Leitsalzes sollen durch Membrantechnologien und Fällung aus der wässrigen Phase selektiv abgetrennt und zurückgewonnen werden. Bei der hydrometallurgischen Aufbereitung soll der nasschemische Prozessweg hinsichtlich der erzielbaren Produktausbeute sowie -reinheit der Metallsalze optimiert werden. Erstmalig kommen dafür besonders umweltschonende, biologisch abbaubare Laugungsmittel zum Einsatz. Mit den erzielten Ergebnissen wird anschließend ein Konzept für ein optimales LIB-Recycling erstellt, welches im Pilotmaßstab getestet werden soll. Das Projekt soll so einen maßgeblichen Beitrag zur Ausrichtung künftiger LIB-Recyclingprozesse leisten.

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

With the finalization of the preliminary study “Project Center for Circular Value Creation”, a sustainable concept for a “Battery Recycling Demonstration Center” in North Rhine-Westphalia has been developed; the center shows numerous unique selling points in Germany due to its scale (demonstration and upscale research) and the comprehensive equipment for closing the loop of used batteries:

Accompanying the project “Research Manufacturing Battery Cell (FFB)” in Münster, the possibility of creating a demonstration center for circular value creation from batteries that is visible beyond the state borders was investigated in the present project. The technical demand for this arises from the ensuring of sustainable e-mobility through the most comprehensive circular economy for the total material flow of batteries. From a spatial point of view, Ibbenbüren offers the best conditions for this, since the complete “battery recycling” value chain within North Rhine-Westphalia can be developed and realized at this location.

In dieser Vorstudie wird ein tragfähiges Konzept für ein Demonstrationszentrum Batterie-Recycling vorgestellt, welches zukünftig auch die im FFB neu entwickelten Zellen berücksichtigt. Es wurden komplexe Flowcharts entwickelt, die den kompletten Batterie-Recyclingbereich abdecken – von der Prüfung über die Demontage und mechanische Aufbereitung bis hin zur Materialkonditionierung und Metallrückgewinnung durch pyro- und hydrometallurgische Verfahren. Die zur Realisierung (Bau und Betrieb) erforderlichen Investitionen und Kosten wurden basierend auf umfangreichen Recherchen sowie Richtpreisangeboten abgeschätzt. Erste Finanzierungsmodelle sind aufgestellt. Darüber hinaus sind erste mögliche Partner und Interessenten aus den Bereichen Anlagenbau, OEM´s und Recyclingunternehmen identifiziert und in einer Liste zusammengestellt. Belastbare (mündliche) Interessensbekundungen sind bereits vorhanden.

IME project management: Elinor Rombach

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

Das Projekt GreenBattNutzung unterstützt die Einzelprojekte der Querschnittsinitiative Batterielebenszyklus in den Clustern Batterienutzungskonzepte und Recycling & Green Battery. Es übernimmt das zentrale Management durch Koordination, Fortschrittskontrolle, Kommunikation und Veranstaltungsorganisation. Zudem erfolgt eine Ergebnisbündelung in einer zentralen Daten-/Dokumentaustauschplattform. Zur Schaffung einer Bewertungsgrundlage werden Referenzen und Standards für die Clusterprojekte definiert. Weiterhin erfolgt die ganzheitliche Bewertung verschiedener Nachnutzungs-/Recyclingoptionen für Batterien hinsichtlich der wirtschaftlichen, technologischen und ökologischen Auswirkungen aus Lebenszyklussicht. Basierend auf den Erkenntnissen aus den Clusterprojekten werden Handlungsempfehlungen für verschiedene Akteure aus den Bereichen Politik, Wirtschaft und Forschung abgeleitet. Der wissenschaftliche Beitrag des IME fokussiert sich auf die Schnittstelle Aufbereitung/Pyrometallurgie.

IME project management: Elinor Rombach

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

Der Ersatz von Energiequellen fossilen Ursprungs durch CO2-neutrale Ressourcen zieht große Veränderungen in zahlreichen Lebens- und Gesellschaftsbereichen nach sich. Insbesondere sind davon die Energieversorgung selbst, Industrie, Verkehr sowie Privathaushalte betroffen. Folglich wird die elektrochemische Energiespeicherung für stationäre Anwendungen sowie in Fahrzeugen mittels Akkumulatoren neben bereits etablierten Einsatzgebieten eine rasant wachsende Bedeutung erlangen. Li-Ionen Akkumulatoren (Li-Ionen-Batterien) sind derzeit, wie auch künftig, die erfolgversprechendsten Batterietypen für diese Anwendungen und führen folglich zu einem steigenden Materialbedarf an Rohstoffen zur Herstellung dieser Batterien. Das Recycling des daraus resultierenden Batterieabfallaufkommens ist, aufgrund des Alleinstellungsmerkmals als wiederaufladbares Energiespeichersystem, essentiell, um eine Sicherstellung von Rohstoffen sowie der Ressourcenunabhängigkeit zu gewährleisten. Die stetig zunehmende Li-Ionen-Akku-Produktion kann insbesondere die Gefahr einer Verknappung kritischer Rohstoffe, wie Kobalt und Lithium, auf dem Weltmarkt zur Folge haben. Der Gewinnung von Sekundär-Rohstoffen aus gebrauchten Li-Ionen-Akkus durch Recycling kommt deshalb zunehmend eine größere Bedeutung zu. Allen Forschungsaktivitäten sowie industriellen Prozessen ist jedoch gemein, dass Lithium als unedles Element bei den Recyclingprozessen nicht oder nur unzureichend zurückgewonnen werden kann und auch die Rückgewinnung des in Batterien enthaltenen Graphits die Industrie und Forschungsreinrichtungen vor Herausforderungen stellt. Dieses Forschungsvorhaben möchte diese Wissenslücke schließen und mit der Rückgewinnung von Lithium sowie des Graphits in Anlehnung und Optimierung bestehender Verfahren einen wesentlichen Beitrag zu einem Zero-Waste-Recyclingkonzept für Li-Ionen-Batterien leisten.

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

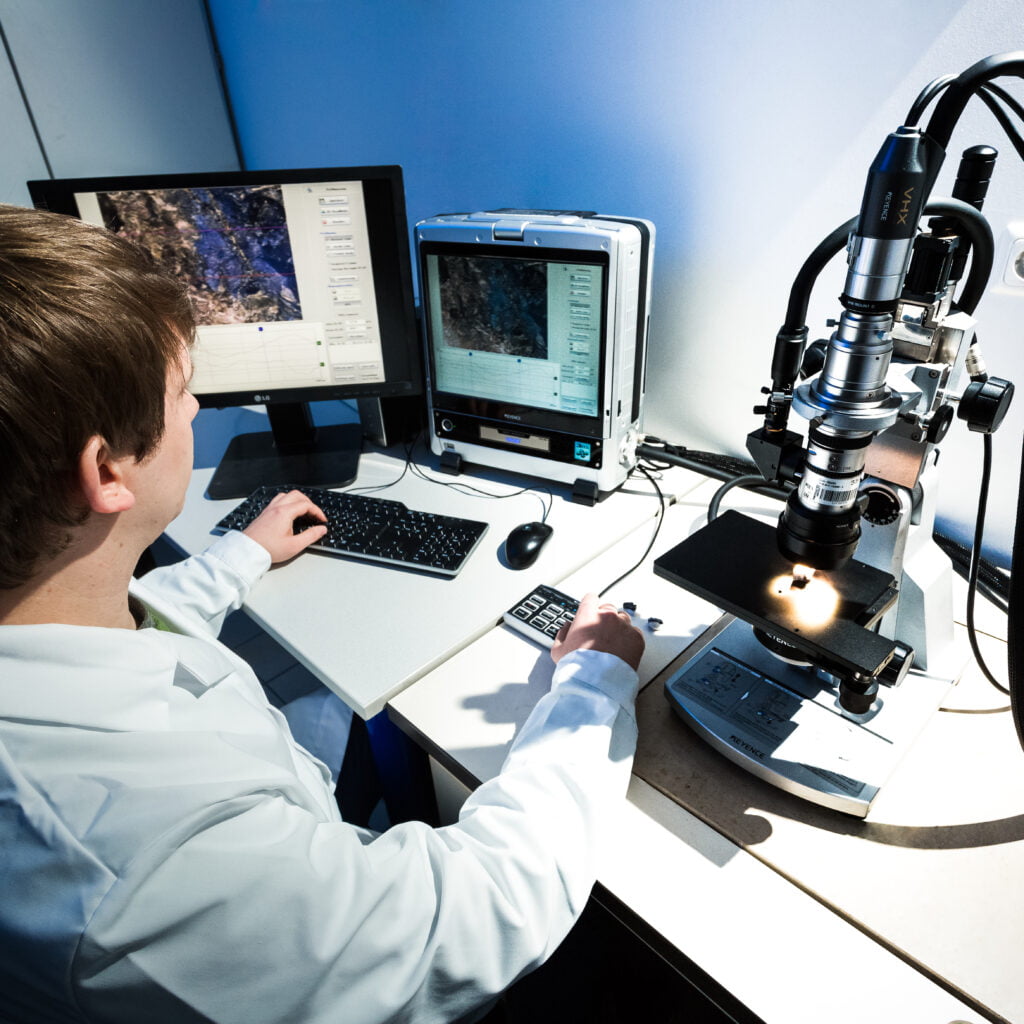

Das Projekt kombiniert die metallurgische Schlackenerzeugung mit mechanischer Schlackenformulierung sowie mit entsprechenden Charakterisierungsmethoden. Der Dienstleistungscharakter des Projektes gegenüber dem SPP ergibt sich aus der Bereitstellung von definiert formulierten und charakterisierten Schlackenproben für weitere Projekte, da es notwendig ist, bereits in der Frühphase der ersten Förderperiode ausreichende Mengen an EnAM-haltigen Schlacken bereitzustellen, um das PP betriebsfähig zu machen. Als EnAM-System wurde LiAlO2 n*SiO2 gewählt, das typischerweise in einem Al-Ca-Mg-Schlackensystem beim metallurgischen Recycling von Li-Ionen-Batterien auftritt. Die Dienstleistung umfasst eine reproduzierbare Synthese der Schlacke, die EnAM-Kristalle in einer definierten Volumenkonzentration sowie mit definierter Kristallgröße enthält. Weiterhin muss die erstarrte Schlacke vor der Weitergabe an die Projekte des SPP zerkleinert werden, um Fraktionen in einem spezifizierten Partikelgrößenbereich und mit definierter Partikelgrößenverteilung bereitstellen zu können. Zusätzlich ist es notwendig, grundlegende Informationen über die Konzentration und Größe (Verteilung) der Li-EnAM-Kristalle bereitzustellen. Dies alles ist die Serviceaufgabe dieses Zentralprojektes. Der Forschungsteil des Zentralprojektes konzentriert sich auf zwei Bereiche: metallurgisch-technologische Untersuchungen mit Quantifizierung der metallurgischen Verarbeitungs-eigenschaften des Li-EnAM-Systems, die komplementär zur Service-Synthese sind, und die Weiterentwicklung von 3D-geometallurgischen Charakterisierungsmethoden und deren Anwendung, um einen tieferen Einblick in den Aufbau und die Zusammensetzung der heterogenen Materialstruktur des Li-EnAM-Systems zu ermöglichen. Die grundlegende ingenieurtechnische metallurgische Herausforderung zielt auf die Betrachtung des Einflusses der Verarbeitungs- und Abkühlungsparameter auf die Eigenschaften der Li-EnAM, z.B. Kristallgröße, Kristallform, Ausbeute, Konzentration oder mechanische Stabilität. Die Arbeiten zur geometallurgischen Charakterisierung zielen auf die Entwicklung einer ganzheitlichen Charakterisierungsmethode für das EnAM, um die 3D-Struktur, elementare und mineralogische Zusammensetzung der erstarrten Schlacke mittels 3D-Röntgentomographie zu quantifizieren. Diese Datensätze werden genutzt, um die volumetrische Kristallisation in 3D und begleitende Entmischungseffekte zu verstehen. Die Bildanalyse der Tomogramme wird weiterhin genutzt, um verschiedene partikel- bzw. kristallbezogene geometrische Größen- und Formparameter abzuleiten. Ein weiterer Schwerpunkt wird auf die Bestimmung des 3D-Verwachsungsgrads innerhalb der EnAM gelegt, z.B. der Phasengrenzen zwischen einzelnen Kristallen.

IME project management: Joao Weiss

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

Die Entwicklung neuer Batteriesysteme bringt weitere, bislang nicht genutzte Elemente wie Silizium, Lanthan oder Zirkon in die Batteriezellen ein. Da für die Sicherstellung der Rohstoffversorgung das Recycling unabdingbar ist, besteht die Zielsetzung des Projektes InnoRec in der Entwicklung bestmöglicher Recyclingwege. Ein zukünftiger Recyclingprozess muss eine hohe Flexibilität aufweisen und dynamisch auf neue Produktionstechniken und Materialien reagieren können. Die zukünftigen Prozesse müssen jedoch ebenso die aktuell für klassische LIB genutzten energieintensiven Prozesse durch niederenergetische, umweltschonende Prozessschritte substituieren. Hierzu sind mechanische, thermische und chemische Prozessstufen in unterschiedlicher Weise einzusetzen und zu verschalten. Die Aufgabe des IME liegt hierbei in der Konzipierung und experimentellen Untersuchung der pyrometallurgischen Recyclingwege. Diese umfassen Pyrolyse, Li-Karbonatisierung, Schmelzprozess und kontrollierte Erstarrung.

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

Libero stellt einen robusten und flexiblen, nahezu abfallfreien Prozess dar, der designt wurde, um alle in gebrauchten Li-Ionen-Batterien (LIBs) enthaltenen Wertmetalle, den Elektrolyten und Graphit für die zukünftige industrielle Umsetzung zurückzugewinnen. Dieses Projekt unterscheidet sich von allen gegebenen industriellen Prozessen dadurch, dass es selektiv und effizient das gesamte Spektrum der LIBs enthaltenen Metalle zurückgewinnt, indem es mechanische Behandlungs- sowie hydrometallurgische Verfahren einsetzt, um höhere Produkterlöse als erwartete Prozesskosten zu erzielen.

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

Si-DRIVE will develop the next generation of rechargeable Li-ion batteries, allowing for cost competitive mass market EVs by transformative materials and cell chemistry innovations, delivering enhanced safety with superior energy density, cycle life and fast charging capability using sustainable and recyclable components. The technology encompasses amorphous Si coated onto a conductive Cu-silicide network as the anode with polymer/ionic liquid electrolytes and Li-rich high voltage (Co-free) cathodes via processes that are scalable and demonstrably manufacturable within Europe. The technology will also demonstrate suitability for 2nd life applications at reduced energy density beyond the primary EV lifetime, prior to cost effective materials recycling, consistent with a circular economy. The consortium boasts the required partner expertise to deliver this technology and spans material design and synthesis, electrochemical testing, prototype formation, life cycle assessment and recycling.

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

Ziel des Projektes MERCATOR ist die Optimierung des Li-Ionen Batterierecyclingprozesses vor dem Hintergrund ökologischer, ökonomischer und versorgungstechnischer Aspekte. Im Vordergrund stehen die Rückgewinnung aller werthaltigen und zum Teil als kritisch eingestuften Sekundärstoffe unter Verbesserung der Ökobilanz der Batterien. Dafür wird ein innovativer Zonen-Ofen im Pilot-Maßstab entwickelt, in dem Fahrzeugbatterien thermisch deaktiviert und für einen anschließenden, materialeffizienten Aufbereitungsprozess vorbehandelt werden. Bisher nicht recyclingfähige Stoffe wie Lithium sollen in einem frühen Prozessstadium mittels Phasentransformation verlustarm zurückgewonnen werden. Parallel ist beabsichtigt, die enthaltenen Oxide zu elementaren Metallen zu reduzieren und diese vorzeitig auszuschleusen, sodass der anschließende hydrometallurgische Prozess entlastet wird. Zusätzlich wird die Aufbereitung des enthaltenen Graphits untersucht, um diesen wieder als Rohstoff bereitzustellen.

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

Eine Lebensdauer von 4000 Zyklen bei 80% DOD und eine Energiedichte von 250 Wh/kg ist ein Ziel für Autobatterien. Das Projekt Batteries2020 unternimmt mehrere Schritte, um die Lebensdauer und Energiedichte großformatiger Lithium-Ionen-Batterien in Richtung dieser Ziele zu erhöhen. Unser Ansatz basiert auf drei parallelen Strategien: 1) hochkonzentrierte Materialentwicklung; 2) Verständnis von Alterungs- und Abbauphänomenen; und 3) Routen zur Verringerung der Batteriekosten. Wir werden Kathodenmaterialien auf der Basis von Nickel/Mangan/Kobalt (NMC) Oxiden verbessern. Solche Materialien haben eine hohe Chance kurzfristig hochskaliert und kommerzialisiert zu werden. Erst dann kann der Entwicklungsaufwand für die Zellentwicklung von der Pilot- zur Massenproduktion umgesetzt werden, eine Voraussetzung für die Qualifizierung in der Automobilindustrie. Wir werden mit Zellen des aktuellen Stands der Technik beginnen und zwei verbesserte Generationen von NMC-Materialien und -Zellen entwickeln.

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

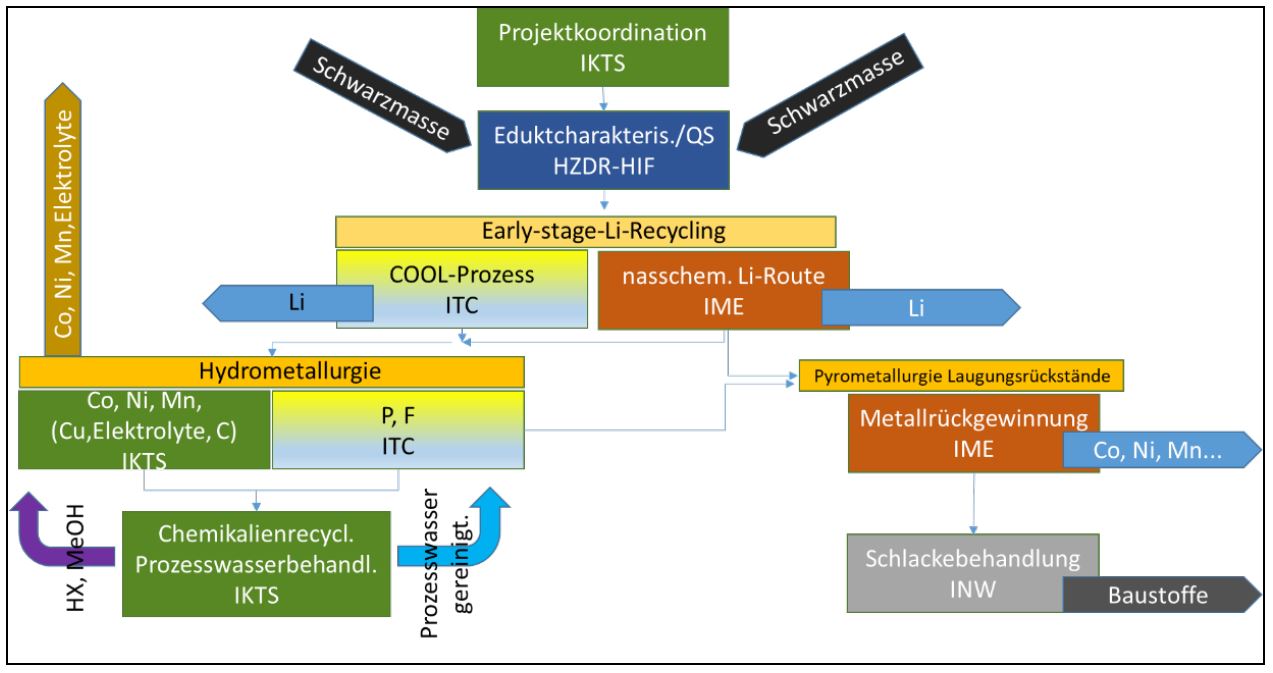

Mit dem Regierungsprogramm Elektromobilität sollen unter anderem Konzepte mit integrierten Demonstrationsanlagen zur Steigerung der wirtschaftlichen Akzeptanz und Wettbewerbsfähigkeit durch Kostenreduktion realisiert werden. Anteilig gehören hierzu auch die bisher hohen Entsorgungskosten der Batteriemodule, die bereits in heute verkauften Elektrofahrzeugen entsprechend der erweiterten Produktverantwortung der Automobilhersteller einkalkuliert werden müssen. Das Entwicklungs- und Pilotierungsprojekt soll im Unterschied zu heute industriell zur Verfügung stehenden und in Entwicklung befindlichen Recyclingverfahren erstmalig ein kostengünstiges Processing mit einer maximierten Rückgewinnung der werthaltigen Batterieinhaltsstoffe verbinden.

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

Hauptziel des Verbundprojektes EcoBatRec war die Entwicklung und Erprobung von wirtschaftlich tragfähigen Recyclingtechnologien für Lithium-Ionen-Batterien von Elektrofahrzeugen. Ein neuer Prozessschritt, die autotherme Vakuumpyrolyse, ermöglicht dabei neue Verfahrensabläufe im Bereich der Zerkleinerung, Klassierung und Sichtung und Trennung der verschiedenen Materialfraktionen. Für die Rückgewinnung von Lithium wurden zwei alternative Verfahren, die Schleppgasverdampfung und die Vakuumverdampfung, untersucht. Die gewonnenen Erkenntnisse werden in einer Demonstrationsanlage genutzt, die von der Accurec Recycling GmbH betrieben wird. Detaillierte Informationen sind dem Abschlussbericht zu entnehmen.

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

Stand der Technik des Recyclings von Nickelmetallhydrid-Kleinstbatterien (NiMH) ist deren Verwendung als preiswerte Nickelquelle bei der Stahlherstellung. Hierbei werden energieintensive Metallinhalte entweder nicht genutzt (Kobalt) oder in einer Schlacke verdünnt (Seltene Erden).

IME project management: Elinor Rombach

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

Im Rahmen von „E-Aix: Elektromobiles Aachen“ werden Nutzfahrzeuge, Elektroroller und Pedelec`s zum Teil direkt angeschafft oder deren Anschaffung gefördert. Im Bereich der Energiespeicherung für diese Fahrzeuge sind zur Zeit mehrere konkurrierende Technologien am Markt erhältlich. Sie unterscheiden sich im Wesentlichen durch Herstellungskosten, Lebensdauer, Gewicht und Energiedichte. Ziel dieser Studie ist, aufzuzeigen welche Veränderungen für Fahrzeugbatterie-vertreiber, Werkstätten, Sammelstellen, Recyclingunternehmen und die Stadt Aachen durch einen Technologiewechsel hin zur Elektromobilität aus Sicht der End of Life Problematik entstehen werden. Dabei werden nicht nur Recyclingkonzepte vorgestellt, sondern auch Zweitnutzungskonzepte und deren Vor- und Nachteile.

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

In letzter Zeit wurde der Entwicklung umweltfreundlicher Technologien für das Recycling von gebrauchten Gerätebatterien in der Welt immer mehr Aufmerksamkeit geschenkt, wobei zwei Hauptaspekte berücksichtigt wurden: die Möglichkeit ihrer Verwendung als Rohstoff in einer Zeit, in der ihre Komponenten begrenzt und teuer wurden, und ihre mögliche umweltschädliche Wirkung, wenn sie nicht ordnungsgemäß entsorgt werden. Mexiko, als eines der bevölkerungsreichsten Länder, hat in den letzten Jahren einen enormen Anstieg des Verbrauchs an technologischen Dispositiven mit tragbaren Batterien erlitten, wie Computer, CD-Player, Walk-man, Handy usw., aber es gibt keine parallele Entwicklung von Sammelstrategien der Batterien und tatsächlichen Regulierungsgesetzen.

Titel

Projekt Art

Förderer

Laufzeit

Research Area

Description

Im März 2008 erhielt das Batterierecycling-Team des IME der RWTH Aachen den erst-mals verliehenen Kaiserpfalz-Preis für herausragende wissenschaftliche Leistungen auf dem Gebiet der „Rückgewinnung von Metallen aus verbrauchten Gerätebatterien“. Mit Hilfe dieser Auszeichnung wurde es möglich, diesen Forschungsbereich auf zu-künftige Li-Ion-basierte Batterien für Anwendungen in EV- bzw. HEV-Automobilen (EV: Electric Vehicle bzw. HEV: Hybrid Electric Vehicle) auszu¬weiten und so weitere innovative Arbeiten auf dem Gebiet der „Angewandten Metallurgie und Werkstofftech-nik der NE-Metalle“ anzustoßen. Ausgangspunkt war die weltweite Forcierung der Entwicklungen zu neuen Li-Ion-Batteriesystemen für Elektrofahrzeuge, welche die bis dato in Kleinserien eingesetzten Nickel-Metallhydrid-Batterien in Zukunft ersetzen sol-len. Im Gegensatz zu üblichen Forschungsarbeiten an neuen Batterien ist geplant, zeitgleich mit deren Entwicklung auch ein geeignetes Recyc¬lingkonzept auszuarbei-ten. Hierdurch soll ein ganzheitliches umweltfreundliches Batteriemanagement-Konzept gemäß der Prämisse „Design for Recycling“ von der Entwicklung über die Anwendung bis hin zum Recycling von Beginn an realisiert werden.

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

Automobile Li-Ion-basierte Batteriesysteme ermöglichen bautypenbedingt erstmalig durch ihre hohen Stückgewichte und eindeutiger herkunfts- und inhaltsbezogener Kennzeichnung die Gewinnung einheitlicher Einsatzstoffe im Recyclingprozess. Infolge können Edukte gleicher Zusammensetzung zusammengestellt und batchweise behandelt werden. Durch diesen Umstand kommt der Gewinnung der hochwertigen organischen Komponenten und des Lithiummetalls eine neue Bedeutung zu. Aufgrund der weltweiten Ressourcen sowie der Verfügbarkeit des Lithiums nimmt dessen Wiedergewinnung einen besonders hohen Stellenwert innerhalb des Forschungsvorhabens ein.

Ziel ist der Nachweis der technischen Durchführbarkeit im halbtechnischen Maßstab sowie die Bereitstellung der Daten für eine ökonomische und ökologische Bewertung des Verfahrens für in der Praxis zu erwartende Anwendungsfälle.

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

Dies ist ein 3-jähriges Projekt zum Realisieren einer vergleichenden Bewertung von 4 verschiedenen Arten von Hochenergie-Lithium-Ionen-Batterie-Technologie für den Einsatz in Traktionsbatterien für den Automobilsektor (vollelektrische Fahrzeuge oder für "Plug-in" Hybrid-Elektro) und für Schwerlast-Hybrid-LKW (Hilfstriebwerk). Die Technologie ist noch nicht ausgereift genug, um den am besten geeigneten Zelltyp für eine bestimmte Anwendung anzuzeigen, daher liefert die Arbeit den System- und Fahrzeugdesignern und auch den Investoren Vergleichsdaten über Leistung, Lebensdauer, Kosten, Recycling und Sicherheit / Missbrauch. Die oben genannten Batterieleistungseigenschaften sind die Schlüsselprobleme für die Kommerzialisierung von Elektro- und Hybridelektrofahrzeugen für Hochenergieanwendungen, die eine große Menge an Energie erfordern, die an Bord gespeichert ist.

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

Das Ziel des Vorhabens ist es, ein innovatives Recyclingverfahren für Altbatterien mit hohem Mengen- und Schadstoffpotenzial zu entwickeln, welches auch die sichere Erfüllung der in diesem Jahr erwarteten europäischen Gesetzesauflagen zur „Recycling Efficiency“ gewährleistet. Entgegen der derzeit vorherrschenden Aufarbeitungspraxis, den Metallinhalt der Altbatterien durch meist mehrstufige Prozesse entweder größtenteils zu verschlacken (Mn) oder mit nur unzureichenden Metallausbeuten zu recyceln (Mn, Zn, Fe), werden durch das hier zu entwickelnde neue emissionsarme ELBO-Verfahren:

- wichtige Gebrauchsmetalle wie Mn, Zn und Fe in deutlich stärkerem Maße in den Rohstoffkreislauf zurückgeführt (Optimierung des Mn-Ausbringens),

- Produktqualitäten verbessert (Erzeugung marktfähiger Metallprodukte),

- Energieverbrauchszahlen der Prozesskette deutlich gesenkt (Prozess-kettenverkürzung und C-Ausnutzung) und

- Prozess- und Transport bedingte Emissionen deutlich vermindert (Prozesskettenverkürzung und abgasarme Elektroofentechnologie).

IME project management: Elinor Rombach

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

The aim and vision of the project is to significantly improve the performance of future high-performance lithium batteries by developing composite electrode layers with customized structuring down to the micro and nano range. The task includes the targeted structure of the separator/electrolyte layers and the electrolyte/electrode interfaces as well as the process technology, which is the prerequisite for reproducible component production. The expected increase in performance relates equally to power and energy density, capacity, cycle stability and the calendar service life of the batteries.

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

Ziel ist die Entwicklung eines reststoffminimierten, prozessstufenarmen Recyclingprozesses, der die metallischen Wertkomponenten (Co, Cu, Al, Fe, Li) und das hochwertige Leitsalz LiPF6 aus den Li-Ion-Batterien in eine solche Form überführt, die den erneuten Einsatz in den Prozess der Batterieherstellung ermöglicht. Ziel ist auch der Nachweis der technischen Durchführbarkeit im halbtechnischen Maßstab sowie die Bereitstellung der Daten für eine ökonomische und ökologische Bewertung des Verfahrens für in der Praxis zu erwartenden Anwendungsfälle. Mit der Verknüpfung mechanischer Verfahren und vakuum-thermischer Behandlungsmethoden sollen aufwendige hydrometallurgische Prozessstufen vermieden werden. Zu den innovativen Kernprozessen des Verfahrenskonzeptes zählen die quasi-isotherme Vakuumdestillation des Elektrolyten temperaturempfindlichen Leitsalzes bei gleichzeitiger Deaktivierung der Li-Ion Zelle, die Zerkleinerung der Batterien und anschließende Sortierung in ein kohlenstoffhaltiges Co-Li-Konzentrat sowie Konzentrate von Kupfer und Aluminium. Das Co-Li Konzentrat enthält das Leitsalz welches nun mit dem zurückgewonnenen Elektrolyten zur Filterung und Wiederverwendung herausgewaschen wird. Über reduzierendes Einschmelzen des Co-Li-Konzentrats wird Co als Metall sowie ein Li-haltiges Schlackenkonzentrat gewonnen. Überführung in Li-Chlorid und anschließende Schmelzflusselektrolyse ermöglicht die Herstellung von metallischem Lithium. Mit diesem ganzheitlichem Ansatz können die wertintensiven Inhaltsstoffe als verkaufsfähige Recyclingprodukte gewonnen werden.

Titel

Projekt Art

Förderer

Laufzeit

Partner

Research Area

Description

Entwicklung eines abfallarmen Verwertungsverfahrens für verbrauchte Ni-MH-Batterien aus den Konsumerbereichen Kommunikation, Video/Audio und Computer zur Rückgewinnung der Wertmetalle, insbesondere Nickel, Kobalt und Seltenerdmetalle und weitgehender Verwertung der anderen Batteriekomponenten.

Die Ergebnisse der Forschungs- und Entwicklungsarbeiten werden nach positiven Projektverlauf der Industrie, insbesondere den Herstellern von Batterien zur Verfügung gestellt, um einerseits die Forderungen des Gesetzgebers hinsichtlich der Batterieverwertung (Batterieverordnung vom April 1998) zu erfüllen und andererseits nachhaltig die Wettbewerbssituation der deutschen Legierungshersteller gegenüber ausländischer Konkurrenz zu verbessern.