Research » Electronic Scrap Recycling

Title

Type

Sponsorship

Duration

Partner

Research Area

Description

Printed circuit boards are the most valuable component in end-of-life electronics in terms of material content. However, due to the complex material composition recycling is challenging. Established recycling routes are based on the technology of copper smelters and require large quantities of input material. Therefore, only a few such special smelters operate globally, and their feed is shipped over long distances from local collectors. This creates a significant CO2 footprint and removes economic opportunities from the countries of origin. In this project a hydrometallurgical process which is suitable for local, small-scale operation is proposed and analysed. The best options for mechanical and thermal pre-treatment and the dissolution process with organic and inorganic solvents are investigated and a comprehensive and flexible hydrometallurgical recycling route is developed. Through a Criticality Assessment, supply and demand of critical raw materials present in printed circuit boards is analysed. Further, the economic as well as the environmental impact of the hydrometallurgical treatment is compared to the conventional smelter technology.

Title

Type

Sponsorship

Duration

Partner

Research Area

Description

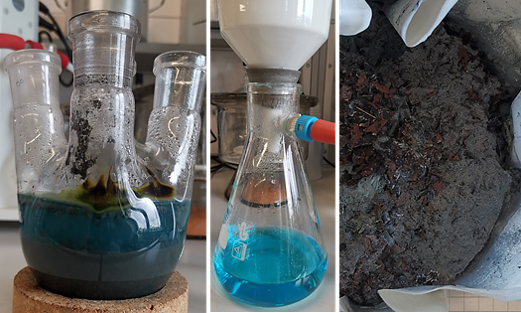

As part of this project, an innovative, environmentally friendly and multi-stage hydrometallurgical process for the recovery of precious metals, especially gold, from used circuit boards is to be developed using non-toxic solvents. With regard to industrial implementation, a scale-up of the best recycling routes from laboratory to commercial scale is to be realized at EMH Service GmbH. In addition, the feasibility of co-extraction of the base metals contained, such as copper, using organic or alternative leaching agents in the process route will be tested at the same time. Finally, the processes developed will be analyzed economically.

Title

Type

Sponsorship

Duration

Partner

Research Area

Description

During the last decades, the evolution of electronic devices push up the consumption of elements like Ta, In, Te, Ga, Se, and several Rare Earth Elements (REE), having a scarce presence in the technosphere. In most cases, the use of these strategic elements is in ppm, and thus, their recovery rate is smaller than 1%. Today, extract these raw materials from Waste Electrical and Electronic Equipment (WEEE) is one of the big challenges of process metallurgy. Typically found in pyrometallurgical slags from WEEE treatment, they are not recovered as their low concentration makes them economically unsuitable for further extraction under the conventional state of the art. Besides their scarcity, natural sources are found outside European borders and, due to their technological importance, are declared as Critical Raw Materials (CRM) by the European Union.Nonferrous metallurgy utilises fayalitic slag to treat several metal scraps such as lead, copper and WEEE because of their low viscosity, melting point and iron immobilisation in the slag. During cooling, fayalite partially decomposes into magnetite and silica. Magnetite share is inverse spinel structure with other compounds that under specific conditions show a magnetic behaviour and can be recovered using magnetic separators. Several authors have reported these strategies to concentrate Fe, Ti and V.This project aims to understand the formation and growing mechanism of artificial magnetitic mineral to concentrate and selectively capture CRM, focusing on Tantalum from WEEE. This phenomenon is strongly affected by the process conditions such as liquidus temperature, cooling rates, oxygen partial pressure in the melt, as well as the oxidation state of different ions in the slag. These different phenomena control the segregation and precipitation of Fe inversed spinel phases from fayalite and capturing several valuable elements during this process. The generation of data for modelling and setting the thermo-physical properties such as viscosity and density in a temperature-dependent system improves the possibilities to achieve control over the formation of the targeted structures.

IME project management: Joao Weiss, Daniel Munchen

Title

Type

Sponsorship

Duration

Partner

Research Area

Description

With an annual production of over 50 million tons and a high content of valuable metals, electronic scrap represents an important secondary resource.However, current recycling technologies are dominated by large-scale, pyrometallurgical processes, so that smaller companies are not able to establish themselves in the market. A new recycling approach involves hydrometallurgical treatment of electronic scrap, which enables selective and environmentally friendly recovery of valuable metals. Prof. Jochen Petersen of the University of Cape Town was awarded the German-African Innovation Prize for his pioneering research in the complex areas of hydrometallurgy. The research project resulting from this award aims to further develop and implement previous operations on a small scale at local recycling companies in South Africa. The process include multi-stage leaching and recovery of precious and base metals as well as the recirculation of the process solution used. The German project partner IME – RWTH Aachen University, lead by Prof. Bernd Friedrich is contributing its expertise in thermal pretreatment to the project. This pretreatment of electronic scrap significantly facilitates the subsequent hydrometallurgical metal recovery. The technical know-how will be transferred through a cooperative workshop. In addition, the results of the project will be made available to local recycling companies to enable the technical implementation. In this context, the socio-economic and ecological sustainability of the project will be ecological sustainability of the project will be critically evaluated in a local African context.

Title

Type

Sponsorship

Duration

Partner

Research Area

Description

The ambition of RemovAl is straightforward: to overcome environmental problems and technological barriers associated with the aluminium industry. Existing processing technologies or those developed by the partners themselves are used to extract base and critical metals from industrial residues such as red mud. These processes are combined, optimized and expanded and the remaining processing residues are reused in the construction sector. If these processes are successfully combined and optimized, a zero-waste concept for the aluminium industry could be developed for the processing of bauxite residues.

In this context, the IME processes hydrometallurgically high-silicate slags for the production of Al and SEE while avoiding silica gel formation.

Further information on the RemovAl project can be found at https://www.removal-project.com/ or contact cdertmann@ime-aachen.de

Title

Type

Sponsorship

Duration

Partner

Research Area

Description

Due to the increasingly tight composite construction of a wide variety of materials, there is still a lack of economically/ecologically sensible and universally applicable recycling processes that enable efficient recovery of the metal content. In the course of the usual processing of collected WEEE old appliances by pre-shredding with subsequent separation, a complex composite of WEEE scrap is produced (≈ 300 kg WEEE scrap per t WEEE old appliance), which is either not recycled at all or is recycled sub-optimally. High contents of valuable metals characterize this WEEE scrap as an important secondary raw material resource that must be recycled in suitable processes with maximum metal yields in terms of environmental protection and sustainability. Its metal value of between 1,000 and 4,000 €/t, depending on the price of the raw material, also justifies suitable reprocessing from an economic point of view.

Title

Type

Sponsorship

Duration

Partner

Research Area

Description

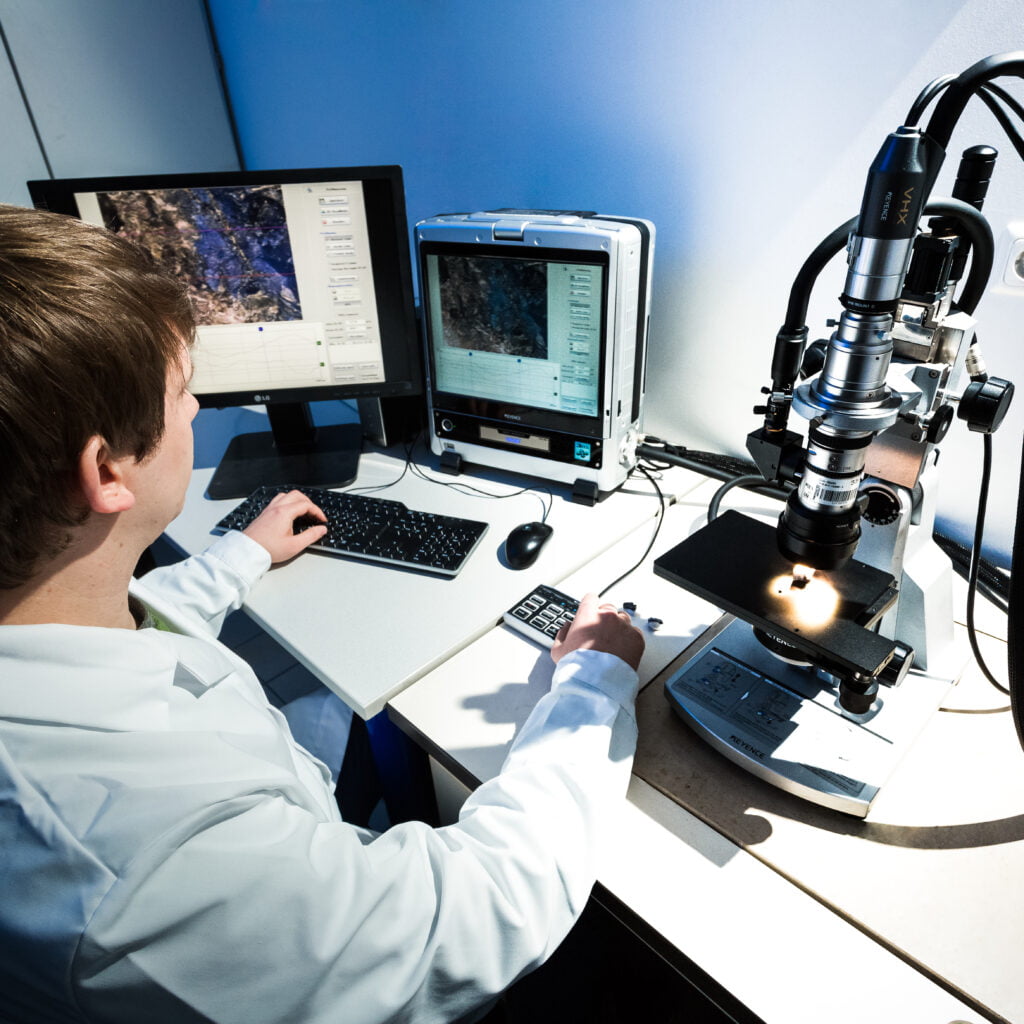

In order to increase the functional recycling of main and trace metals, a real-time analysis system for the characterisation of metal-rich processing products “ARGOS” is to be designed and implemented in this project, and the application of this system to actors in the value chain is to be tested. ARGOS is based on the combination of a continuous, sensor-based particle characterisation with mathematical derivations taking into account empirically known material properties. The scope of the characterization is based on the specifications and requirements of the downstream metallurgical processes (Fe and NE metallurgy) and includes information on

– the content of the main constituents iron, aluminium and copper, including characteristic alloys,

– on the contents of precious metal-bearing recyclable materials and alloying metals of strategic economic importance,

– about non-metallic impurities (organic, ceramic and glass) and

– to physical data such as color, surface structure, shape, piece weights, etc..

Title

Type

Sponsorship

Duration

Partner

Research Area

Description

For several years Bayer has been developing a highly efficient new electrode technology for NaCl electrolysis, the so-called oxygen depolarized cathode (ODC). Used ODCs contain 70% Ag, 25% Ni and 5% PTFE. Recycling is massively hindered by the PTFE. The removal of PTFE before recycling Ag and Ni would make the processes much more efficient. The aim of this project is therefore to develop an economically and ecologically efficient recycling process for Ag and Ni from NaCl-ODC electrodes on a technical scale. The recycled silver is to be reused for the production of highly active catalysts for new ODCs.

Title

Type

Sponsorship

Duration

Partner

Research Area

Description

The overall objective of the project proposal is to develop a thermal and highly selective recovery process for strategic recyclables from thin-film modules for which no process proposal has been able to provide economic proof to date.

Title

Type

Sponsorship

Duration

Partner

Research Area

Description

The aim of the project s-AmOx is the development of secondary antimony oxides, which can be used in conjunction with plastics as flame-retardant housing components. The use of antimony from electronic and battery wastes is not currently practiced, but may result in the substitution of primarily derived antimony from China, thus significantly reducing import dependency for this strategic raw material. The use of antimony for flame retardancy is always coupled with an oxidation to antimony trioxide (Sb2O3), and in terms of functionality, no difference may arise between primary and secondary produced antimony oxide.

Title

Type

Sponsorship

Duration

Partner

Research Area

Description

The aim of the project is the development of an environmentally friendly melting process for WEEE scrap by adapted converter work in an innovative Top Blown Rotary Converter of copper metallurgy with high processing capacity. In this low-emissivity and extremely fast-reacting bath melt reactor, it is intended to enable efficient metal removal while avoiding the generation of new waste by utilizing the plastic content (as a reducing agent or substitute for fossil energy carriers). The project targets a recovery rate of> 97% for copper and precious metals and at least 80% for tin, lead and nickel. It is necessary to obtain as co-product a marketable mineral phase with low value metal contents (<1% Zn, <0.5% Cu, <0.1% Ni, Sn, Pb, <20 ppm Ag, <5 ppm Au). The material use of the organic components as a reducing agent will lead to the saving of fossil energy carriers.

Title

Type

Sponsorship

Duration

Partner

Research Area

Description

-

The classic method for removing tin, arsenic and antimony from lead is the oxidation of the metal by atmospheric oxygen in the refining furnace. However, the question of the possibility of selective removal of the accompanying elements of the factory lead and the question of the achievable speed of refining remained unclear. From an operational point of view, the most selective removal of accompanying elements and the maximum enrichment of the oxide phase with the accompanying element to be removed, which enables an increase in production and facilitates the further processing of the oxide phases, are particularly important,

Thermodynamic calculations have shown that the order of oxidation of the accompanying elements is dependent on the oxygen content (oxygen partial pressure) of the gas mixture, composition of the lead and temperature and that even the oxygen concentration of the air causes a simultaneous oxidation of all accompanying elements in the lead.

Title

Type

Sponsorship

Duration

Partner

Research Area

Description

The aim of the research project is to develop a multi-stage treatment process for sawing and grinding sludges that originate from the cutting process of solar wafers from crystalline silicon blocks. The product of the presented recycling process is high-purity silicon of so-called solar grade quality, which is to be reintroduced directly into the production process of solar silicon blocks in the PV industry for improved use. This reduces the amount of sawdust in the PV industry that has to be disposed of to a quarter. A Successful recycling of 65-75% of the 5 tonnes of sawdust per MW of solar cell power results in 3.5 tonnes of recovered silicon per MW. Based on the current consumption of 16 to 18 tons of silicon raw material per MW of photovoltaic power generated, the purchased amount can be reduced to approximately 13 tons. The project will prove that reprocessing costs are well below 20 €/kg per recovered silicon.

Title

Type

Sponsorship

Duration

Research Area

Description

For the mainly used metals, iron, aluminium, copper, zinc and lead, recycling has to be assessed very differently, as there are considerable differences in the areas of application, the quantities produced and the process engineering, as well as in the ratio of used scrap and residual materials. None of these metals alone could provide representative results in terms of an optimal recycling rate for metals. In the case of secondary metal production, a distinction must usually also be made between scrap and residual material recycling. The various input materials must first be classified according to their metal content, the impurities and the present chemical form.

Title

Type

Sponsorship

Duration

Partner

Research Area

Description

The aim of this joint research project is to significantly reduce lead and zinc losses from the material cycle caused by the dumping of slag from the lead and zinc industries. For this purpose, the lead and zinc contents from the slags are to be significantly reduced using an electric arc furnace for introducing the reducing agent, and the technical and economic limits of this process are to be investigated. The operation mode of the electric arc furnace (Zn evaporation; Pb/Zn/Fe reduction; slag guidance) must be optimised in such a way that the resulting product slags reliably achieve a final concentration of

Pb < 0.1%

Zn < 1 %

while avoiding iron reduction. It is to be achieved that in the long term, even after a reduction of the statutory eluate limit values possibly envisaged in the future, it is not to be classified as subject to monitoring.