Research » Titanium Metallurgy

Titanium is called the material of the future. This title results from the unique combination of properties such as good corrosion resistance, high strength and biocompatibility with low density. Due to these properties, titanium alloys are increasingly being used in areas such as aerospace, automotive, chemical or medical technology.

Despite its relative commonness as the fourth most abundant element in the earth’s crust, titanium remains denied a wide industrial use. The reason for this is the high price of the metal, which results from the production costs. To reduce these and thus to allow the titanium the broad mass accessibility is a big challenge in research.

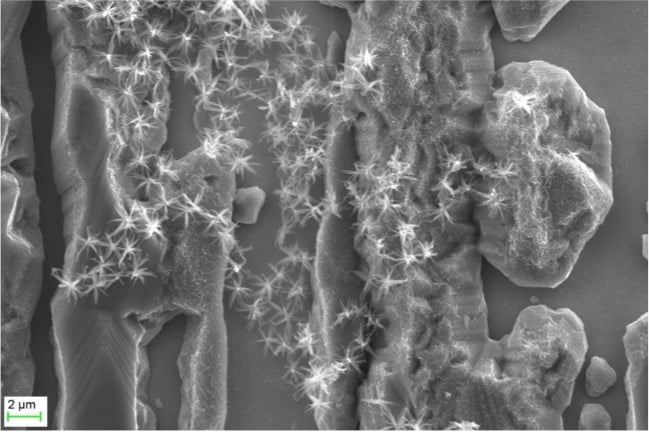

A reduction in process costs could be achieved both by minimizing process steps and increasing efficiency. For this reason, investigations have been made in the past for the direct recovery of titanium from rutile. By aluminothermic conversion of the TiO2 with aluminum so the costly chlorination and reduction step in the Kroll-method could be omitted. Furthermore, optimizations of this process have been made such as the mechanical activation of the rutile (reduction of booster up to 30%) or the study of alternative booster agents (reduction of chlorine emissions).

The recycling of the more frequently used titanium powders in additive manufacturing is also being pursued. In the HDH process, these powders are processed and prepared for further usein metallic 3D-printing.

Contact:

Alumni:

- M.Sc. Carolin Maier geb. Mazurek

- Dipl.-Ing. Jeraldiny Becker

- M.Sc. Frederic Brinkmann

- Dr.-Ing. Gözde Alkan

- M.Sc. Alexandra Daldrup

- M.Sc. Christoph Vonderstein

- Dr.-Ing. Jan-Christoph Stoephasius

- Dr.-Ing. Qin Peng

- Dr.-Ing. Peter Spiess

- Dr.-Ing. Claus Lochbichler

- Dr.-Ing. Seyran Hassan-Pour

- Dr.-Ing. Ksenija Milicevic Neumann

- Dr.-Ing. Joerg Hammerschmidt

- Dr.-Ing. Jan Hecht geb. Reitz

- Dr.-Ing. Rafael Bolivar

- M.Sc. Aybars Güven

- Dr.-Ing. Claudia Oosterhof geb. Kommer

- Dipl.-Ing. Björn Rotmann

Project List

- EURO-TITAN: Decarbonized Titanium Recovery from Aluminium and Titanium Production Residues

- MA4AM – Mechanical alloying for Additive Manufacturing

- Skin Pro – Forging of cast blanks for economically and resource-saving production of highly loaded TiAl low-pressure turbine blades

- Low-emission synthesis of titanium alloys

- Innovative refractory and induction melting systems for titanium and titanium alloys; Knowledge transfer project

- TIAl2020 – Increases in raw material efficiency for TiAl components

- Melt flow electrolytic production of titanium alloys

- Engine Breakthrough Components and Subsystems

- Adoption and qualification of the VIM-ESR-VAR Recycling Process for Ti and y-TiAl Alloys

- Process stage-minimized production of titanium and titanium alloys

- Influence of calcium and fluorine on the properties of y-titanium aluminides

- Limits and Influencing of the Pollution Levels of Titanium Recycling Alloys for reuse

- Closure of the material circuit for titanium – Development of a recycling process for scrap of foundries and mechanical processing centers

- Pulse-, heat- and mass transfer in argon-ESU-refining using the example of titanium

- Development of a cost-effective process chain for the production of aluminum-containing titanium materials

Publications

| Year | Publications |

|---|---|

| 2025 |

article in scientific journal

Recycling Magazine, International, Spring 2025

|

| 2025 |

congress or congress paper

https://doi.org/10.30544/MMESEE100

|

| 2025 |

article in scientific journal

Recovery of Titanium and Aluminum from SecondaryWaste Solutions via Ultrasonic Spray Pyrolysis. Metals 2025, 15, 701. https://doi.org/ 10.3390/met15070701

|

| 2025 |

article in scientific journal

S. Stopić, D. Kostić, N. Nikolić, D. Životić, M. Rosić, M. Perušić, B. Friedrich, Production оf Titanium Dioxide Nanopowders from Red Mud (7-28)

|

| 2025 |

congress or congress paper

Influence of TiO2 and CaO Addition in Synthetic Fayalitic Slag Targeting Tantalum Mineral Enrichment

9th International Slag Valorisation Symposium

|

| 2024 |

article in scientific journal

Surfaces 2024, 7, 1096–1108. https://doi.org/10.3390/surfaces7040072

|

| 2024 |

article in scientific journal

Minerals 2024, 14, 1151. https:// doi.org/10.3390/min14111151

|

| 2024 |

article in scientific journal

Journal of Power Sources 624 (2024) 235582; https://doi.org/10.1016/j.jpowsour.2024.235582

|

| 2024 |

article in scientific journal

Materials 2024, 17(19), 4779; https://doi.org/10.3390/ma17194779

|

| 2024 |

article in scientific journal

Metals 2024, 14(4), 402; https://doi.org/10.3390/met14040402

|