Research » Technology Metals (Extraction and Recycling)

Critical metals are, by definition, metals that are of high economic importance and at the same time exhibit significant supply risks. Elements that are ascribed as especially critical are, for example, rare earth elements, platinum group metals, but also antimony and niobium.

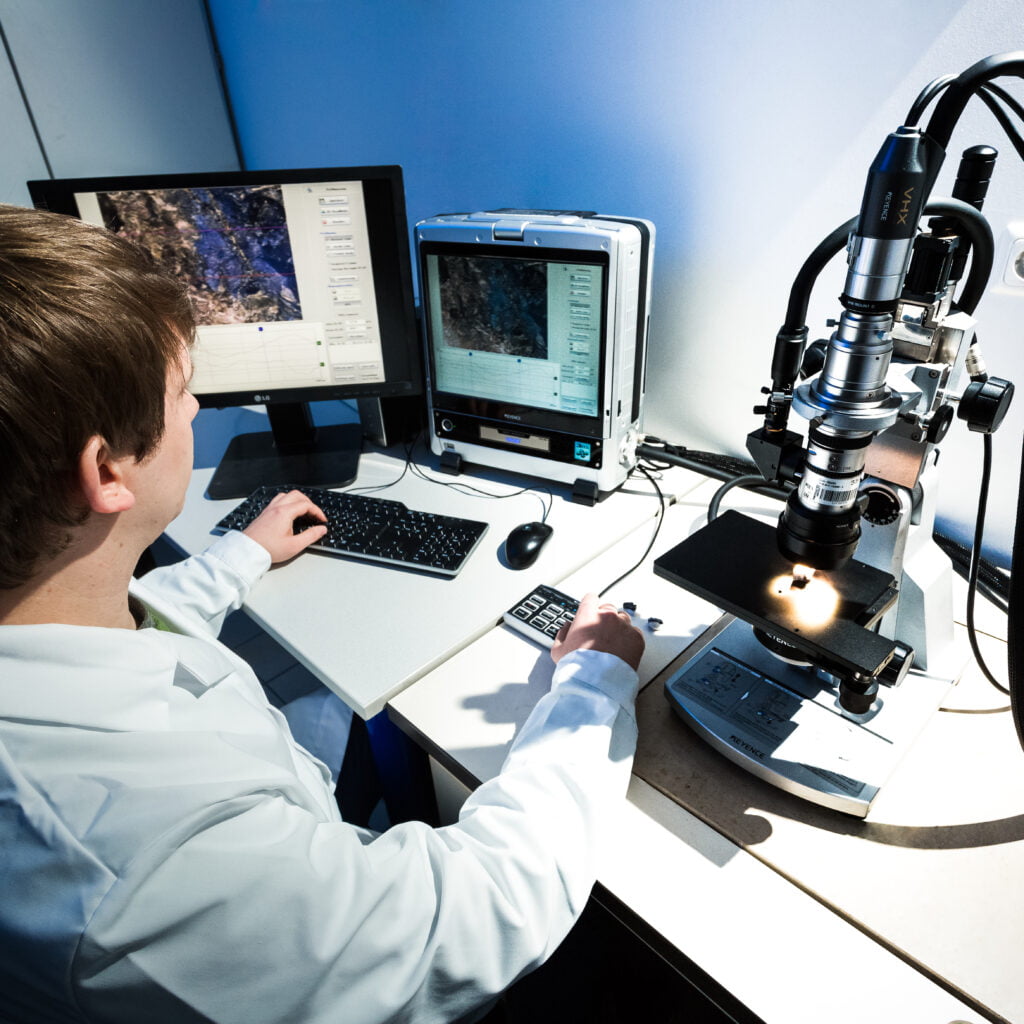

At IME, pyrometallurgical as well as hydrometallurgical processes for economic, efficient and environmentally friendly treatment and extraction of critical metals are investigated. The following list abstracts some of our current research topics in this field:

– alternative Bismuth extraction route from lead industry residues

– extraction of rare earth elements from eudialyte ore via cascade leaching

– precious metal recycling by application of suitable slag systems

– extraction of antimony trioxide from lead industry residues

– metallothermic reduction of scandium compounds

Alumni:

- Dr.-Ing. Yiqian Ma

- M.Sc. Dominic Feldhaus

- M.Sc. Frederic Brinkmann

- M.Sc. Alexandra Daldrup

- M.Sc. Jürgen Maier

- M.Sc. Jil Schosseler

- Dr.-Ing. Diana Vieten, geb. Michaelis

- Dr.-Ing. Stephanie Kruse

- Dr.-Ing. Ann-Kathrin Maurell-Lopez geb. Pophanken

- Dipl.-Ing. Charlotte Merkel

- Dr.-Ing. Florian Ruschmann

- Dr.-Ing. David Friedmann

- Dr.-Ing. Marek Bartosinski

- Dr.-Ing. Milena Stopic

- Dr.-Ing. Hanno Vogel

- Dr.-Ing. Daniel Voßenkaul

- Dr.-Ing. Guizhi Zeng

Project List

- International Masters Programme in Energies & Green Hydrogen(IMP-EGH)

- SeRoBatt – Secondary sources of critical raw materials for battery cell production – potentials, recovery, resynthesis

- H2Giga Cluster (ReNaRe, Peuker)

- ScaVanger. Sustainable supply of Nb, Sc and V from liquid waste from TiO2 plants

- Development of an innovative process for the recovery of CoCr from dental residues

- REGINA – Rare Earth Global Industry and New Applications

- Production of Scandium compounds and Scandium Aluminum alloys from European metallurgical by-products

- Integration of NRW recycling competencies into the European raw material community KIC EIT Raw Materials

- Transformative technologies for enhancing hydrometallurgical recovery rates of Li, Co and Ag

- Development of a sustainable process route for the internal European processing of bismuth trees by combining innovative refining processes

- German Resource Research Institute – GERRI

- Recyclability of rare metals when dismantling nuclear facilities

- Core-Partner Beteiligung an Knowledge and Innovation Communities-Umsetzungsstrategie im KIC InnoLife und KIC Raw MatTERS

- KIC Raw Materials – Application by RWTH Aachen University

- EURARE: Development of a sustainable exploitation scheme for Europe’s Rare Earth ore depoits

- Direct low-process extraction of solar silicon from raw silicon while avoiding silane chemistry

- Preparation of a German contribution to the European revision of the „Reference document on Best Available Techniques in the Non Ferrous Metals Industries“ (briefly: NE-BREFs)

Publications

| Year | Publications |

|---|---|

| 2025 |

congress or congress paper

Proceedings of EMC 2025

|

| 2023 |

congress or congress paper

European Metallurgical Conference 2023 (EMC 2023); DOI: 10.13140/RG.2.2.18029.97767

|

| 2023 |

congress or congress paper

TMS 2023: Light Metals 2023 pp 1204–1206; DOI: 10.1007/978-3-031-22532-1_161

|

| 2022 |

article in scientific journal

ACS Sustainable Chemistry & Engineering 10(18):6063-6071, DOI: 10.1021/acssuschemeng.2c01056

|

| 2021 |

congress or congress paper

Mater. Proc. 2021, 5, 86; https://doi.org/10.3390/materproc2021005086; International Conference on Raw Materials and Circular Economy, Athens, Greece, 5. – 9. September 2021

|

| 2020 |

article in scientific journal

Journal of Materials Research and Technology (IF 3.327) DOI: 10.1016/j.jmrt.2020.02.063

|

| 2019 |

article in scientific journal

Journal of Materials Research and Technology, Volume 8 (2019) DOI: 10.1016/j.jmrt.2019.11.049

|

| 2019 |

article in scientific journal

Scientific Reports 9 (1): 1-10, DOI: 10.1038/s41598-019-48390-z

|

| 2019 |

article in scientific journal

Industrial Engineering Chemistry Research 58(32); DOI: 10.1021/acs.iecr.9b02411

|

| 2019 |

article in scientific journal

Hydrometallurgy 185 (2019), pp. 266–272 DOI: 10.1016/j.hydromet.2019.03.008

|