Research » Electronic Scrap Recycling

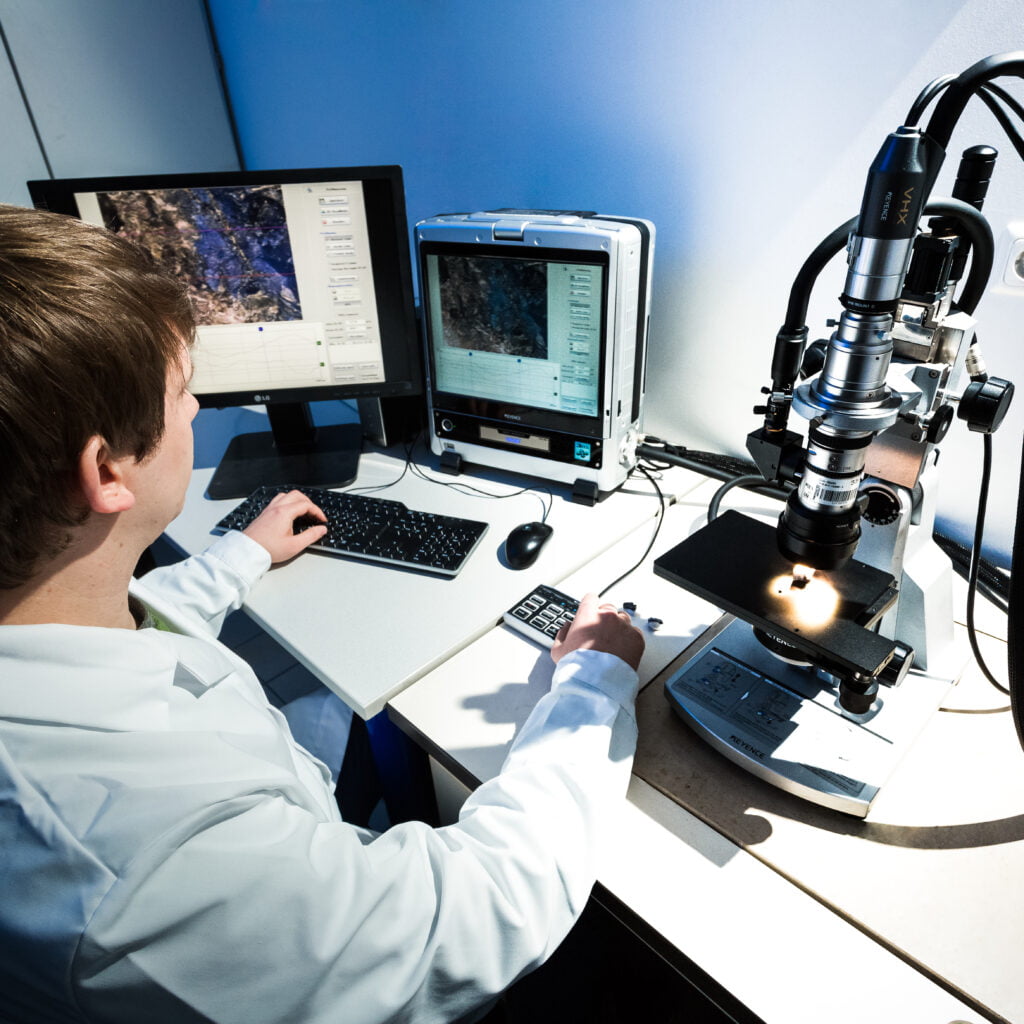

The IME pursues the objective to use the high potential of WEEE as a resource for various metals by developing a sustainable metallurgical recycling process. The focal point is the recovery of base metals (copper, aluminum), precious metals (gold, silver, platinum and palladium) as well as critical elements (gallium, germanium and indium). Currently, five doctoral studies examine different approaches of hydro- and pyrometallurgical processes concerning their selectivity, efficiency and flexibility. These processes aim at the treatment of several waste streams (such as printed circuit boards, shredder dust or whole smartphones) to recover various valuable metals with minimal losses. By elaborating several single methods, a process concept will be developed, which enables the recovery of individual elements through a flexible combination of these methods, adapted to a given waste stream and particular requirements.

Key aspects: Reductive and energetic use of organics; thermal preparation of rest fractions (Pyrolysis); autothermal metallurgy, microwave heating; slag design and controlled solidification for metal concentration; critical metals recovery; autogenious pellets with respect to phase separation; TBRC furnace development for treating pure WEEE; scraps synergies by waste mixtures.

Project List

- Short Circuits – Development of a small-scale processing route for the localised short-loop recycling of waste electronic circuit boards

- HEEERO – Hydrometallurgical Electrical and Electronic Equipment Recycling Optimization

- Formation of Ta-rich magnetite phases in WEEE recycling slags through modification and controlled cooling

- Development of a pyro-/hydrometallurgical process for the recovery of valuable metals from WEEE through small-scale operations in South Africa

- RemovAl – Removing the Waste Streams from the Primary Aluminum Production and Other Metal Sectros in Europe

- Development of a foam slag reactor for the autogenous recycling of the finest electronic waste

- Increasing Functional Recycling by Real-Time Analysis – Argos –

- Ag recycling of electrolysis electrode

- Recovery of rare strategic metals from EOL thin film PV modules (“PhotoRec”)

- Development of secondary antimony oxides for use in plastic materials

- Autothermal metal recovery from WEEE scrap through energy-optimized zero-waste metallurgy

- Improvement of selectivity in the removal of Sb, Sn and As from recycled lead

- Recovery of solar silicon from production residues of solar wafer production

- Optimum use of secondary metals – Economic and ecological limits of metal recycling

- Development of a process for the reduction of lead and zinc contents for the long-term avoidance of dumping and production of slag product, zinc oxide and lead metal

Publications

| Year | Publications |

|---|---|

| 2024 |

poster

Kolloquium SPP2315 – Projekt B8

|

| 2023 |

congress or congress paper

8th International Slag Valorisation Symposium, 220–24

|

| 2021 |

congress or congress paper

European Metallurgical Conference (EMC) 2021, virtual conference, June 27-30

|

| 2020 |

article in scientific journal

Minerals 2020, 10(4), 309 DOI: 10.3390/min10040309

|

| 2019 |

congress or congress paper

Proceedings of the 10th European Metallurgical Conference (EMC) 2019, June 24-26, Düsseldorf, Germany

|

| 2018 |

article in scientific journal

Journal of Sustainable Metallurgy 4 (2018), pp. 155-156

|

| 2018 |

article in scientific journal

Journal of Sustainable Metallurgy (2018), Online-Artikel DOI: 10.1007/s40831-018-0159-3

|

| 2015 |

article in scientific journal

Chemie Ingenieur Technik, 2015

|

| 2015 |

congress or congress paper

Proceedings of the 8th European Metallurgical Conference (EMC) 2015, June 14-17, Düsseldorf, Germany

|

| 2012 |

article in scientific journal

Chemie Ingenieur Technik, Vol. 84 (2012), No. 10, pp. 1733-1739

|