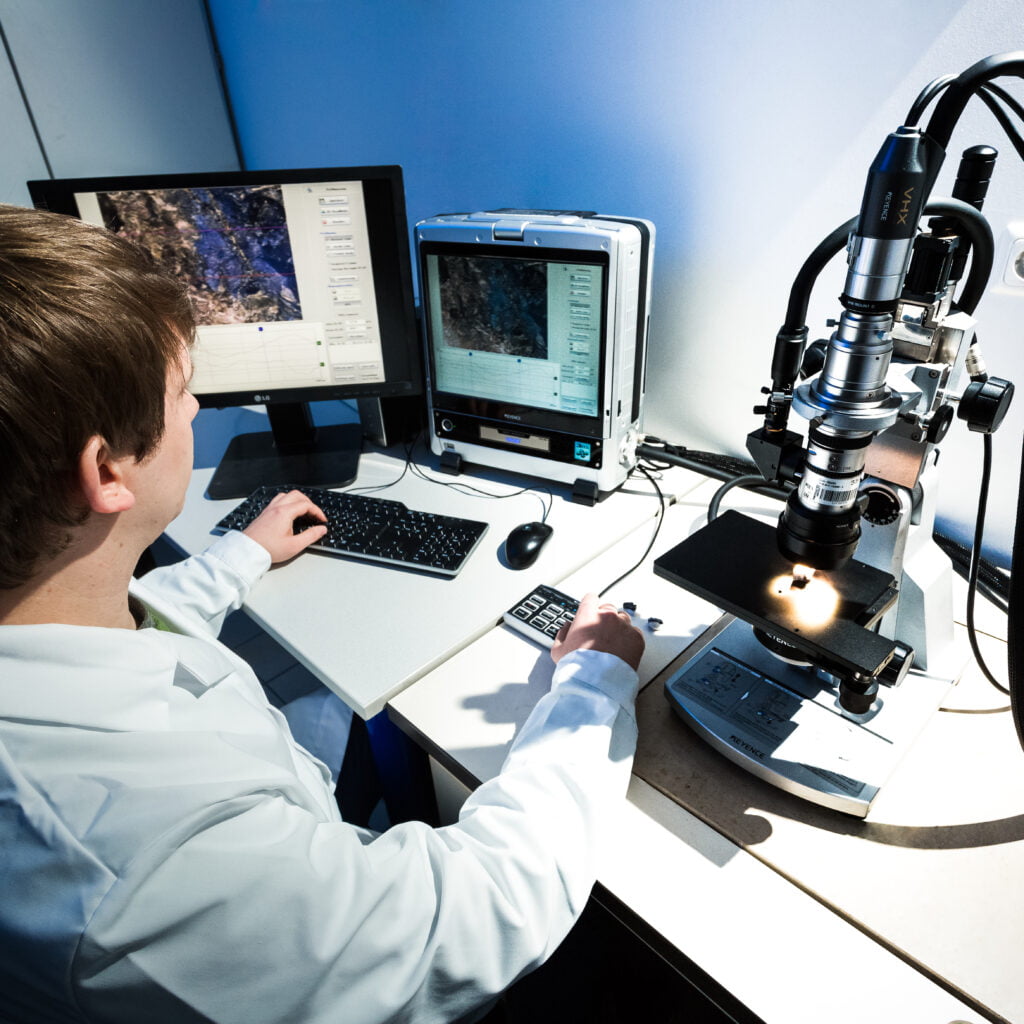

Research » Alloying Metallurgy

Alloying metallurgy is confronted with increasing complexity, as requirements of metallic high-tech materials rise with regard to composition, cleanliness and homogenity. In order to comply with strict tolerances, metallurgical vacuum processes are applied, which allow, for instance, melting of metals with high oxygen affinity, removal of dissolved gases or non-metallic inclusions as well as selective distillation of volatile metals. The available equipment at IME for these purposes comprises various vacuum induction furnaces, a pressure-slag-remelting unit and a vacuum arc furnace. Currently research on the following projects is conducted:

– Alternative production methods of Cu-Cr-alloys

– Influence of a rotating electrode on the ESR-process

– Processing of lead-containing copper alloys in consideration of current EU regulations

Project List

- Influencing the refining effect and the solidification behavior in the electroslag remelting process by a rotating metal / slag system

- Influence of the interfacial reactions in the transition zone of zinc coating steel substrate by varying the chemical composition of the substrate areas near the surface and the immersion bath composition

- Corrosion protection and property profile of electrochemically deposited ZnSnX alloy layers with the addition of passive-film-forming elements X

- Reduction of zinc losses by integrating continuous processing of contaminated zinc melts in the production process of hot-dip galvanizing companies

- Alloy design of Al- and Al-Li materials for thixoforming

Publications

| Year | Publications |

|---|---|

| 2025 |

article in scientific journal

Metals 2025, 15, 1045. https://doi.org/ 10.3390/met15091045

|

| 2025 |

article in scientific journal

https://doi.org/10.1007/s10853-025-11313-7

|

| 2025 |

congress or congress paper

Proceedings of EMC 2025

|

| 2025 |

article in scientific journal

Mining, Metallurgy & Exploration https://doi.org/10.1007/s42461-025-01337-7

|

| 2024 |

article in scientific journal

ChemEngineering 2024, 8(3), 63; https://doi.org/10.3390/chemengineering8030063

|

| 2024 |

congress or congress paper

S. Wagstaff (ed.), Light Metals 2024, The Minerals, Metals & Materials Series; https://doi.org/10.1007/978-3-031-50308-5_78

|

| 2023 |

congress or congress paper

European Metallurgical Conference 2023 (EMC 2023)

|

| 2023 |

article in scientific journal

Metallurgical and Materials Transactions B (2023); https://doi.org/10.1007/s11663-022-02710-3

|

| 2022 |

poster

20th Plansee Seminar, May 30 – June 3, 2022, Reutte (Austria)

|

| 2021 |

article in scientific journal

Metals 2021, 11, 997; https://doi.org/10.3390/met11070997

|