Equipment » Fundamentals

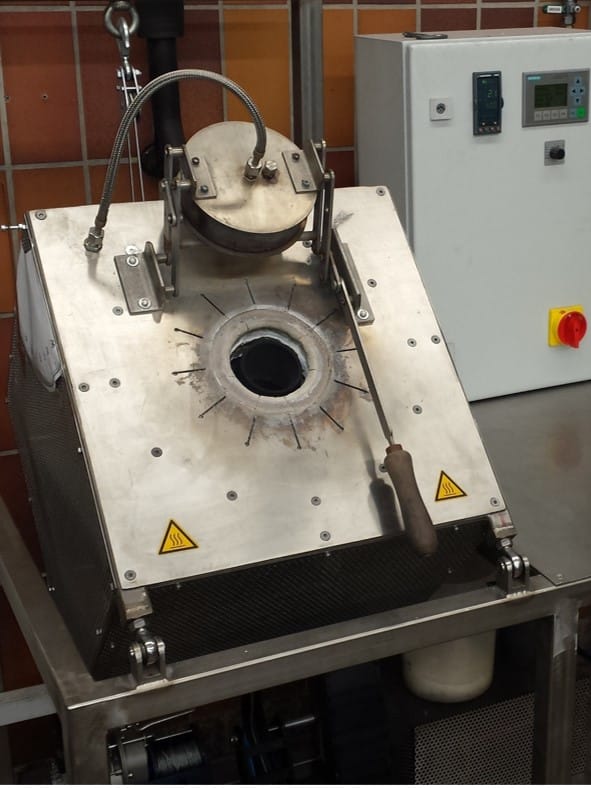

Mini tiltable rotary kiln

Application area:

- Aluminium Recycling

- Salzschmelzen/Salzschlacken Eigenschaften

Performance data

- max. Temperature 1300 ° C

- tiltable angle: 0-65 ° to the vertical

- outter crucible: graphite, ØInside = 65 mm, height = 250 mm.

- Current line 32A

- 4-40 revolutions min-1

- Power 2 kW furnace

- Inert gas influence argon, nitrogen, 10 l / min

- Graphite crucible material

Contact person

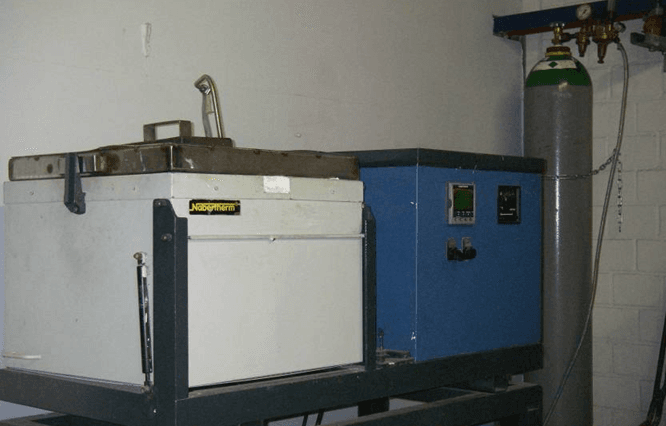

Naberther furnace – chamber furnace

Application area:

- Melting metal, burning of glas, porcelain and stoneware

Performance data

- Resistance furnace – five sited heater

- Heater programable

- Maximum temperature: 1300°C

- Air dicharge opening in center of the furnace cover for a constant air exhaust

- Dimensions : heigth x width x deepth 460 x 400x 530

- Volume: 100 l

Contact person

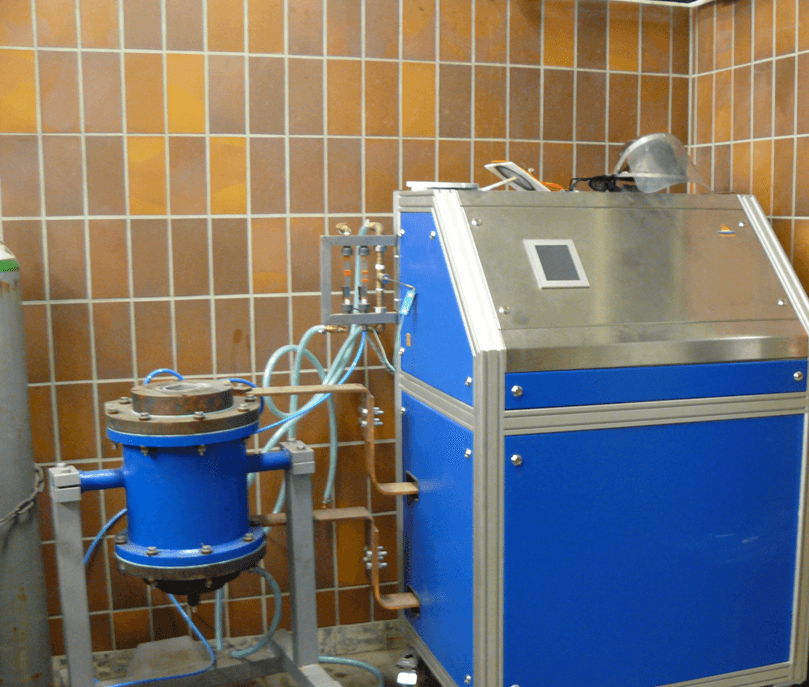

Nabertherm furnace

Application area:

- Metal melting

- Salt melting

Performance data

- Resistance furnace

- Diameter of shank:

Φ= 18 cm height= 13 cm - Heater programable, Maximum temperature: 1200°C

- Inert gas atmosphere possible

- Application of thermowell possible

Contact person

SOLO furnace

Application area:

- Muffle can be insert into the furnace chamber by pivot arm

- Heat-treating-furnace up to 1550°C

- Different gas atomosphere possible: Ar, CO

- Dimension of furnace chamber: height x width x depth 200 mm x 270 mm x 450 mm

Performance data

- Seven resistance heating elements made of MoSi2

- Heating power: 14 kW

- Continuously adjustable temperature control

- Different temperature profile adjustable

Contact person

Tammann-furnace

Application area:

- Application in high temperature range (max. 2000°C)

- Equilibrium experiments

Performance data

- Inert atmosphere

- Resistance heated

- Open and closed operation possible

- Maximum temperature 2000°C

- Programmable temperature profile

Contact person

Measuring instrument for surface tension

Application area:

- Measuring the surface tension of liquid metals, salts and slags, essential in refining and recycling processes

Performance data

- Acuracy of measurement 2-10 %

- Temperature rang up to 1600 °C

- Heating rate 3-5 K/min

- Sample volume from 50 ml

- Two-capillary methode applicable

- Sources of measurement error: Inaccuracies of capillary diameter and capillary imersion depth

Contact person

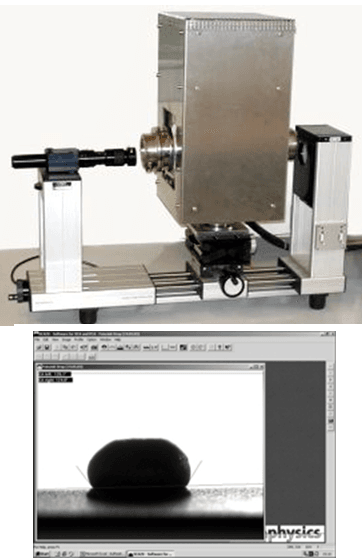

Measurement instrument of wetting angle

Application area:

- Measuring of wetting angle between liquid and solid

Performance data

- Possible gas atmosphere: H2, N2, Ar, air

- Temperature: up to 1000°C

- Photo/video recording of liquid drops

- Automatic/manual measuring of wetting angle

Contact person

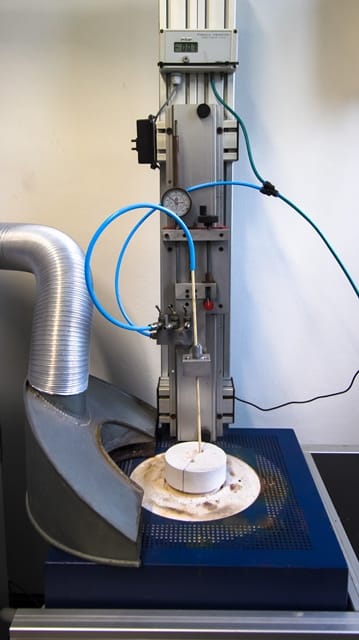

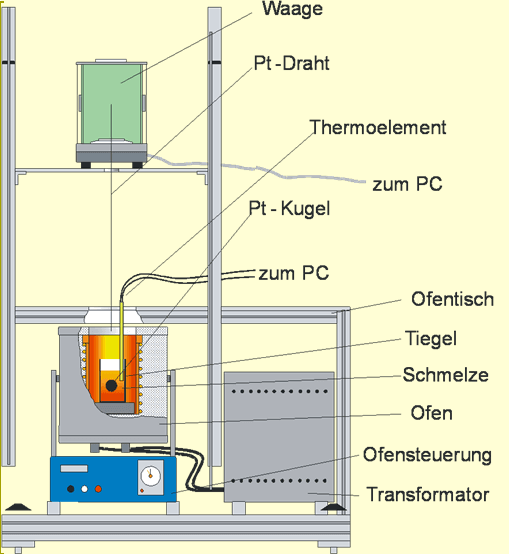

Density measurement device

Application area:

- Density measurement of liquid metals, salts und slag,necessary for the investigation of phase separation and determination of the dynamic and kinematic vicosity

Performance data

- Accuracy of the method 0,1-1%

- Temperature range up to 1500 °C

- Heating rate 3-5 K/min

- Minimum sample size 50ml

- Choice of material (wire and test sample) important

- Sources of measurement error: Surface tension of the melt and thermal expansion of the test sample

Contact person