Equipment » Alloy & Metals

Pressure Induction Furnace

Application area:

- Alloys synthesis on a e.g Ni, Fe or Co basis

- Pressure metallurgy of alloys with highly volatile components (e.g. Al-Li, Al-Mg-Sc, Mg)

- Purging gas treatment of silicium

- Degassing treatment of metallic melts

Performance data

- Maximum crucible volume: 2 l

- Melting power: max. 50 kW

- Frequency: 10 kHz

- Overpressure: max. 4 bar

- Use of ceramic and graphite crucibles possible

- Casting into a water-cooled copper crucible possible

Contact person

Electro Slag Remelting (ESR) / Pressure Electro Slag Remelting (PESR)

Application area:

- Remelting of special alloys (Removing NonMetallic Inclusions and Impurities)

- Remelting of special steels

- Remelting of nickel-based alloys

- Deoxidation of titanium-alloys

Performance data

- Power supply: thrystor control: 6 kA at 66.6 V

- ESR Electrodes max. Ø 100 mm, mold Ø 150 mm, h = 800 mm

- PESR Electrodes max Ø 110 mm, h = 1340 mm, mould Ø 170 mm, h = 1250 mm

- Inert gas up to 50 bar overpressure

Contact person

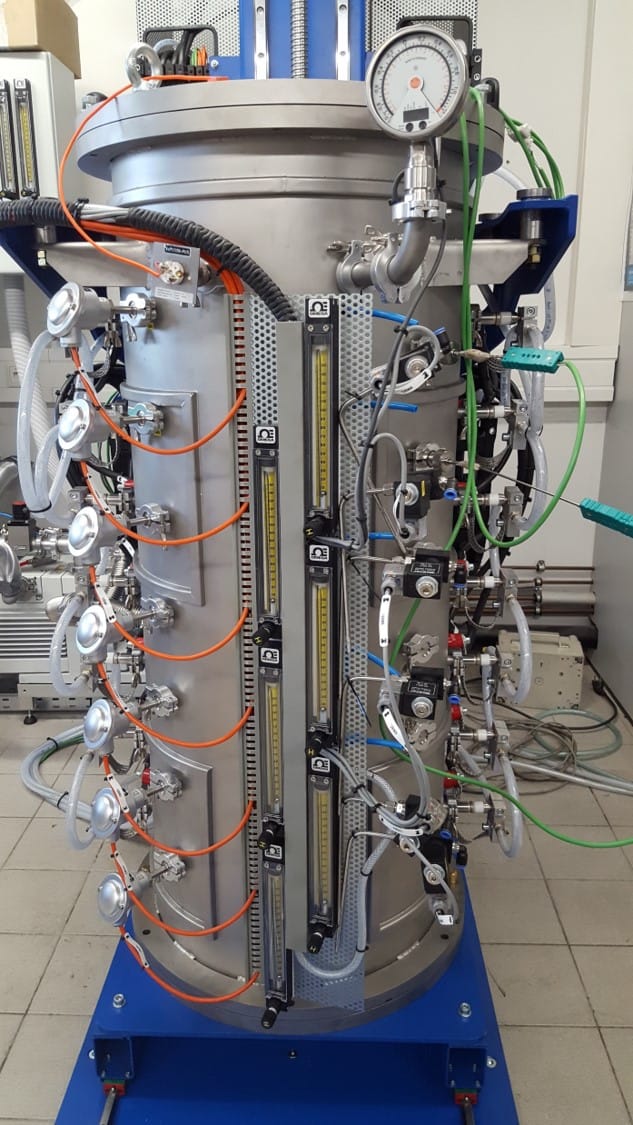

Junker VIM 800-inductively heated hot wall furnace

Application area:

- Melting furnace under protective gas or vacuum

- Vacuum treatment of cast iron

- Vacuum distillation of metals, alloys and metallic products

- Casting openly with ladle into ingot molds

Performance data

- Power rating: 600 KVA

- Melting capacity: max. 300 KW, min. 80 KW

- Frequency: 150 Hz

- volume: max. 100 l

- melting pot Dimensions: 700 mm; 380 mm diameter

- Operating vacuum: 1 • 10-2 mbar

Contact person

Mini Vacuum induction furnace

Application area:

- Equilibrium analysis under vacuum or inert gas atmosphere

- Homogenisation melting

- Research in melt behaviour of material mixture

- Casting under vacuum or inert gas

Performance data

- Frequency 10 kHz

- Nominal power 5 kW (depending on crucible and material components)

- Vacuum up to 10-3 mbar

- Inert gas atmosphere max. 800 mbar

- Melting capacity 500g copper

- Tapping under vacuum or inert gas atmosphere

Contact person

Vacuum induction furnace

Application area:

- Melting experiments under vacuum,

- alloy volatile elements in any metal-matrix

- Preparation of the alloys,

- no Chargierungs-and no Gießmöglichkeit

Performance data

- Achievable temperature max. 1600 ° C

- Achievable pressure 10-2 – 10-1 mbar

- Melt volume max. 2 l

- Achievable frequency max. 4 kHz

- Power max. 40 kW

- Protective gas (Ar / N 2) options

- Process control, reducing the leakage rates of great importances

Contact person

Vacuum induction furnace PVA Tepla VSG010

Application area:

- Alloy synthesis of diverse alloy systems

- Vacuumdestillation with condensate deposition

- Basic experiments of process development

- Homogenous melting of slags

Performance data

- Melting power: max. 40 kW

- Frequency: 10 kHz

- Max. melting volumen: 2,5 Liter

- Lock device for on-line sampling, post loading and temperature measurement with immersion thermocouple

- Possible application for ceramic and graphite crucible

- Water cooled rotary disk

Contact person

Vacuum induction furnace PVA VSG100

Application area:

- Synthesis of Ni-, Fe-, Co-, and Al-based alloys

- Recycling of titanium aluminides

- Attempts to online parameters detection in the melting process

Performance data

- Max volume: 14 liters (equivalent to about 100 kg of steel)

- Melting capacity: max. 150 kW

- Frequency: 2 kHz

- Lock device for online sampling, Nachchargierung and temperature measurement with immersion of thermocouples

- Possible use for ceramic crucible and graphite crucible

- possible Casting via water-cooled copper mold

Contact person

Vacuum Arc Remelting ALD VAR L 200

Application area:

- Remelting of Ni- and Fe-Base alloys

- Melting of alloys with high melting point or high reactivity in an intensely water cooled copper crucible under vacuum

- Research to increase the metallic purity grade

Performance data

- Melting capacity: max. 180 kg Stahl

- Maximum electrode length: 1140 mm

- Available mould diameter: 120, 160, 200 mm

- Maximum melting current: 7,5 kA

- Maximum operational voltage: 40 V

- Coaxial current supply

- Vacuum: up to 10-5 mbar

Contact person

Cooled Finger crystallization furnace

Application area:

- Purification of metals via fractional crystallization

Performance data

- Widerstandsbeheizt

- Einschmelzen unter Vakuum (5×10-2 mbar) und/oder Schutzgasatmosphäre

- Dimension des Tiegels: bis max. 200Ø, 300 H (mm)

- Maximales Schmelzmasse: ~20 kg Aluminium (8,5 Liters)

- Stromversorgung: 32A, 400V, 22KVA

- Rotierenden Kühlfinger integriert im Ofen.

- Bis 100 RPM

- Kühlungsgas bis 180 L/min

- Hochreines Graphit als Schutzmantel für den Kristallisationseinheit mit 38 AØ, 22 IØ, 220H (mm)

Contact person

Static crystallization furnace

Application area:

- Purification of metals via fractional crystallization

Performance data

- Heating via resistance heaters

- Melting under vacuum (10-2 mbar) and/or inert atmosphere

- Vertical furnace with seven independent-controlled heating zones

- Bottom cooled (Ar)

- Optional gas cooling (Ar) for each zone

- Crucible dimensions: oØ 95, uØ75, 1000H (mm)

- Maximum melt capacity: ~8,5 kg Aluminum (3,5 Liters)

- Power supply: 63A, 400V, 27KVA

Contact person

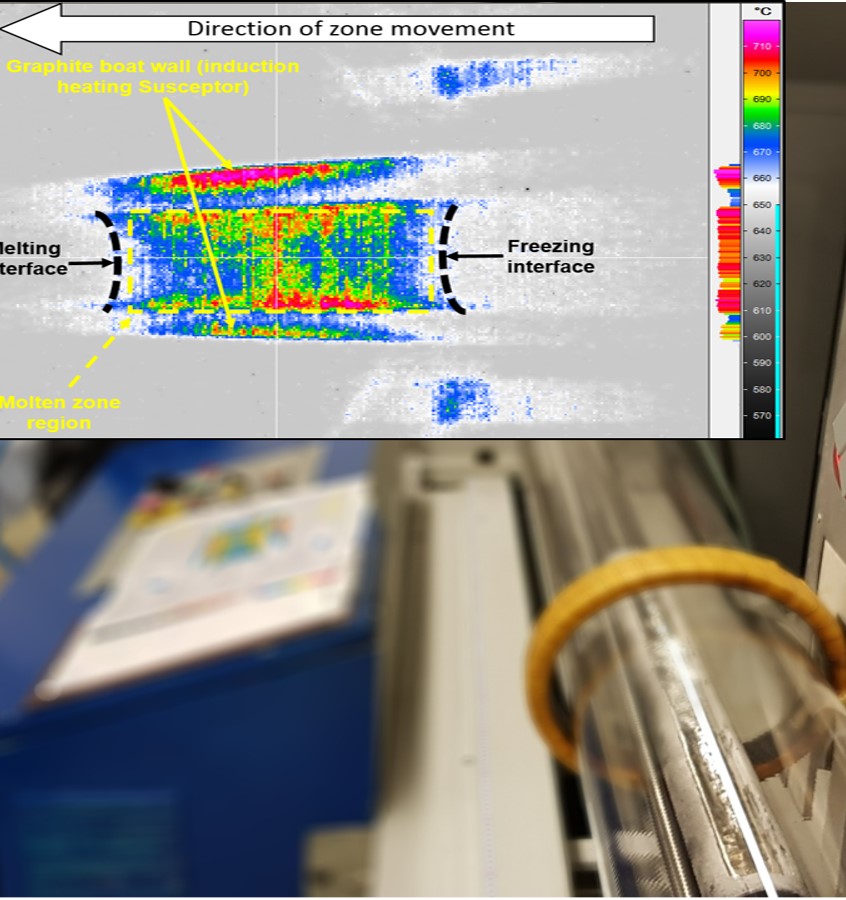

Zone melting system

Application area:

- Refining of metals (e.g. Al, Sb)

Performance data

- Horizontal zone melting in a quartz glass tube

- Feed speed of the induction coil: max. 2 mm / min

- Length: 1500 mm, diameter: 170 mm

- Power: max. 45 KW; frequency: max. 10 kHz

- Vacuum up to 1 mbar, with Ar or N2 Atmosphere

Contact person