Ausrüstung » Prozessmetallurgie

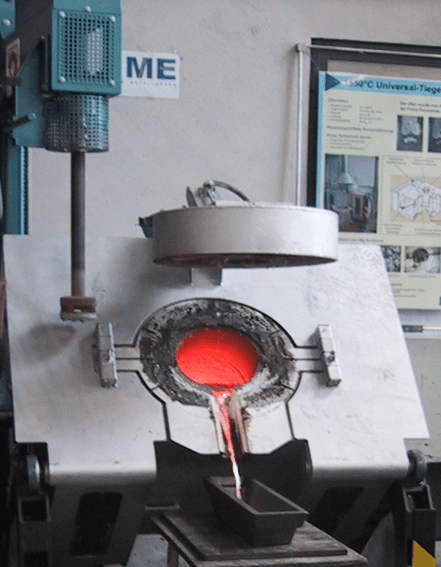

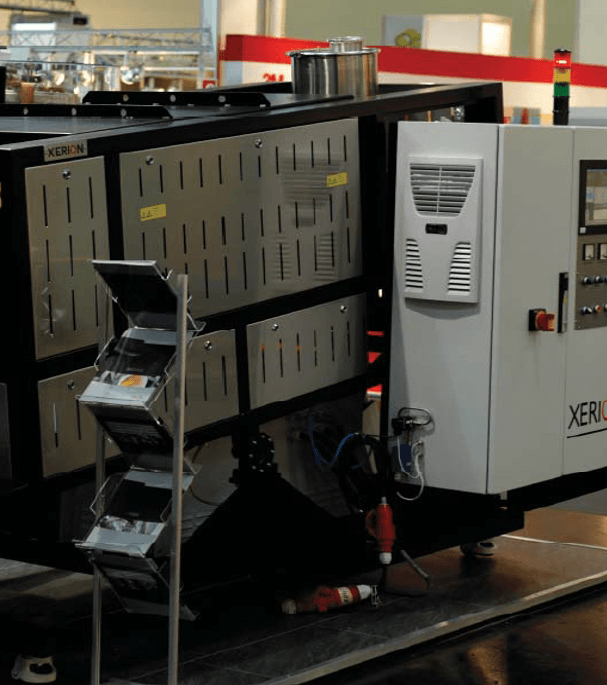

35l kippbarer Widerstandsofen

Application area:

- sicherheitstechnisch speziell für Magnesiumschmelzen ausgelegt (Fe-Tiegel)

- Schmelzen von Al, Cu, Pb, Zn in Fe oder Graphit Tiegel

- Schmelzbadbehandlung möglich mit installiertem, industriellen, vollautomatischem Foseco Rühr- und Entgasungsgerät

Performance data

- Der mit SiC Stäben widerstandsbeheizte Ofen

- Volume: 35 l

- Feinmotorischer, hydraulischer Kippantrieb erlaubt ein kontrolliertes Dosieren während des Abgusses (ferngesteuert)

- Hydraulischer Deckel (ferngesteuert) mit Schutzgas-Ringleitung

- Die Heizleistung des Ofens beträgt 46 kW

- Temperatur im Ofen kann gradgenau eingestellt werden

- Notauslauf im Boden zur gezielten Schmelzabfuhr bei Tiegelbruch

Contact person

DC-Lichtbogenofen (GLBO)

Application area:

- Carbothermische Herstellung von Silizium / Aluminium

- Batterierecycling

- Schlackenmetallurgie

- Stahlmetallurgie

- Kupfermetallurgie

Performance data

- Gleichstrombetrieb

- Trafo Anschlussleistung 700 kVA

- Herddurchmesser 0,95 m

- Gefäßhöhe 1,45 m

- Messtechnik zur Erstellung einer Energiebilanz

Contact person

DC-Lichtbogenöfen (KLBO & MLBO)

Application area:

- Recycling von AlMn, ZnC oder Lithium-Ionen Batterien

- Recycling von Schlacken

- Reduktion oxidischer Komponenten

- Herstellung von AlSi-Vorlegierungen und Silizium

- Herstellung von Ferrolegierungen und Nichteisenlegierung

- Verwertung von Reststoffen

Performance data

- Kleiner Lichtbogenofen (KLBO) = 1,5 l Schmelzvolumen

- Mittelgroßer Lichtbogenofen (MLBO) = 4,5 l bzw. 12 l Schmelzvolumen

- Strom: 120-700 A; Spannung 24-70 V

- Standardtiegel: Graphit

- Kopfelektrode (30 mm/50 mm): Graphit

- Bodenelektrode: Kupfer, wassergekühlt

- Abguss durch Kippen des Ofens

- Temperaturüberwachung an Bodenelektrode, Ausmauerung und Abgas

- Möglichkeit der Set-Up-Modifikation nach Kundenwunsch

Contact person

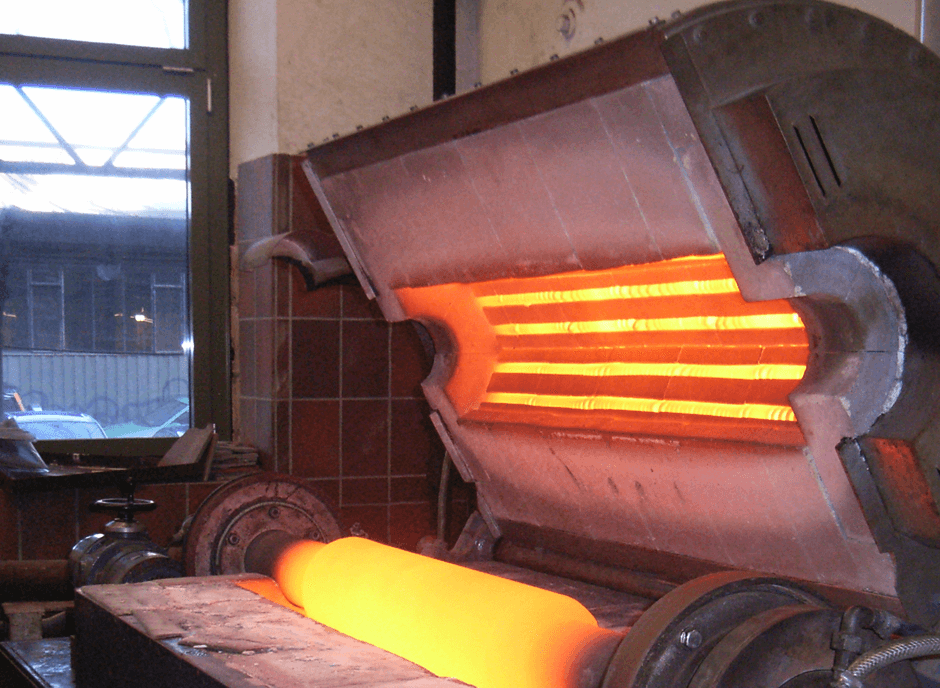

Top Blown Rotary Converter(TBRC)

Application area:

- Aluminiumrecycling mit Salzschlacke

- Konverterprozesse durch Sauerstoff auf- oder einblasen

- Schmelzaggregat

- Schlackenarmschmelzen

Performance data

- Rotationsgeschwindigkeit bis zu 10 U/min

- Flexibler Energieeintrag durch luft- oder sauerstoffbetriebenen Erdgasbrenner (max. 500 kW)

- Konverterlanze

- Stufenlos einstellbarer Neigungswinkel des Schmelzaggregats

- Austauschbare Ofengefäße (Variation in Schmelzvolumen und Feuerfestmaterial)

- Gefäßvolumen beträgt 100 l bzw. 1000 l (in Abhängigkeit des Ofengefäßes)

Contact person

Hochdrucklaugungsautoklav

Application area:

- Laugung unterschiedlicher Erze und Konzentrate

- Recycling unterschiedlicher metallurgischen Stäuben

- CO2-Speicherung und Nutzung als Karbonate

- Reinigung von Wälzoxid

Performance data

- Temperatur max.: 300°C

- Reaktionsvolumen: 1-10 l (2 Reaktoren)

- bis 200 bar

- Rührerdrehzahl: 2000 U/min

- Probenentnahme ist vorhanden

- Mögliche Gasatmosphäre: CO2, O2, H2, N2, Ar, Luft

- System für Säuredosierung ist vorhanden

- Online Datenerfassung

Contact person

Kaskadenlaugung

Application area:

- Reinigung von industriell verunreinigigtem Abwasser

- area of application: environmental protection

Performance data

- Konventionelles Verfahren zur Fällung von gelösten Metallen

- Selektive Entfernung mit Hilfe von pH-Wert-Verschiebung

- Etablierte Methode zur Reinigung von metallhaltigem Abwasser

- Neutralisierung mittels Natronlauge oder Kalkmilch

- Vollautomatisierte Chemikalienzugabe über pH-Transmitter

- Online-Überwachungssystem mit Messwerteerfassung

- skalierbare Durchsatzkapazität durch modulare Erweiterung/Erhöhung

- Kostengünstiger Verbrauch von Energie und Ressourcen

Contact person

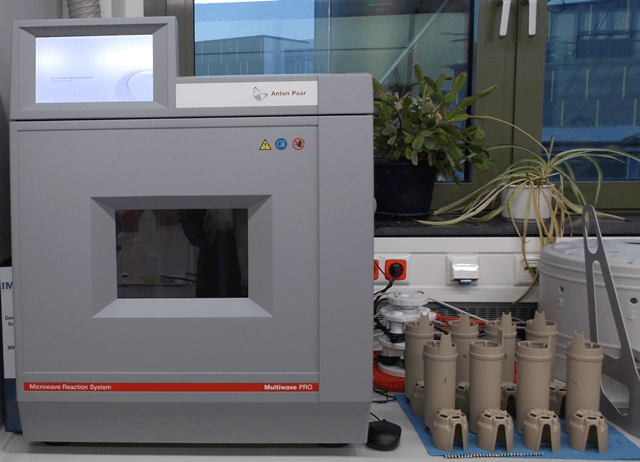

Mikrowelle Anton Paar

Application area:

- Mikrowellenunterstützte Probenvorbereitung

- Mikrowellenunterstützte chemische Synthese

- Schneller und vollständiger Aufschluss in geschlossenen Gefäßen

- Extraktion mit organischen Lösungsmitteln von organischen und anorganischen Proben unter hohem Druck und bei hoher Temperatur

Performance data

- Stromversorgung: 230V, 50Hz, 3680VA

- Leistung Magnetrons jeweils 850W

- Mikrowellenleistung 1500W

Contact person

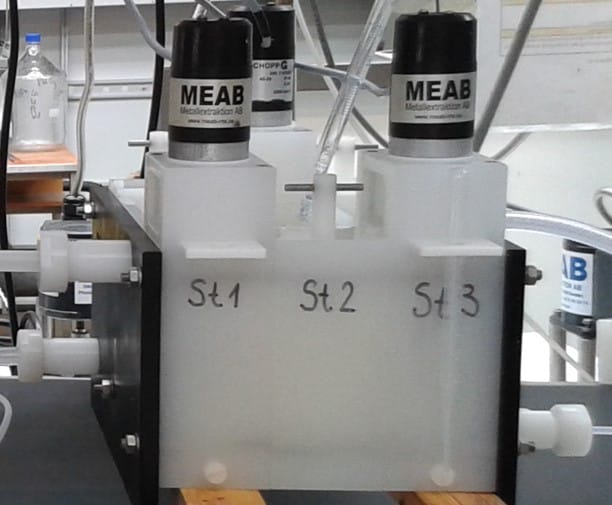

Solventextraktionsanlage

Application area:

Typ: Mixer-Settler

- Hydrometallurgie

- Solventextraktion

- Selektiv arbeitendes Separationsverfahren

- Entfernung von Verunreinigungen

- Aufkonzentrierung der Lösungen

Performance data

- Mixer-Settler Units 0,5

- Kontinuierliche Betriebsweise

- Mehrstufiges Verfahren: insgesamt 5 Mixer-Settler Units

- Einstellbare Flussrate (max. 10 L/Stunde)

Contact person

Ultraschallprozessor von hielscher

Application area:

- Reinigung von Glasgeräten

- Ultraschallunterstützte chemische Synthese

- Verbesserung der Durchmischungen von Dispersionen

- Entgasung von Flüssigkeiten

Performance data

- Arbeitsfrequenz: 24 kHz

- Regelbereich ± 500 Hz

- Amplitudenregelung 20-100%

- Verschiedene Sonotrodensurchmesser

Contact person

Drehrohrofen

Application area:

- Verflüchtigung von zinkhaltigen Vorstoffen

Performance data

- Arbeitstemperatur bis 1100°C

- Rotation stufenlos einstellbar

- Drehrohre für reduzierende, oxidierende und schwefelhaltige Atmosphäre

- Einleitung von Spülgasen

Contact person

High temperature vacuum rotary kiln

Application area:

- 10 U/min, 10° Neigungswinkel: Verweilzeit von Pulver beträgt ca. 2min (0°C - 1500°C)

- 0 U/min, 0° Neigungswinkel: Kein Materialaustrag (Batch-Prozess) (0°C - 1500°C)

- Keramisches Arbeitsrohr (Tmax = 1600°C) maximale Korngröße von Input-Material beträgt 15 mm.

- Edelstahl Arbeitsrohr (Tmax= 1000°C) maximale Korngröße von Input-Material beträgt ca. 30 mm.

Performance data

- Maximaltemperatur: 1.600°C

- Arbeitsrohre: I) Aluminiumoxidkeramik, Qualität C610, II) Hochtemperaturfester Edelstahl 1.4841

- Innendurchmesser: 150 mm

- Gesamtlänge: 2.000 mm

- Heizung: Heizelemente: Molydändisilicid

- Heizzonen: Drei (vollautomatisch einzeln regelbar)

- Beheizte Länge: 1.000 mm

- Drehzahl: 1 bis 10 U/min

- Neigung: 0 bis 10° (vollautomatisch regelbar)

- Atmosphäre: Vakuum (bis 10mbar), Inertgas (Mit-, Gegenstrom)

Contact person

Metallothermische Reduktion

Application area:

- Möglichkeit zur Metallerzeugung aus hochschmelzenden Metalloxiden

- Metallothermische Reduktion mit Aluminium, Magnesium als Reduktionsmittel

- Autothermer Prozess, nur Initialzündung notwendig

- Herstellung von Refraktärmetallen und Vorlegierungen (TiAl, Ti24Al16V, CuCr, NbCr, etc.)

Performance data

- Reaktorvolumen bis 200 l (entspricht ~ 60 kg einer Ti-Vorlegierung als Zielmaterial)

- Geringer apparativer Aufwand

- Schnelle Reaktionszeiten (2 - 20 Min.)

- Temperaturarbeitsbereich (einstellbar über Energiedichte): 1 700°C - ca. 2 600°C

- Fahrweise: Batchbetrieb; Inline-Casting zur direkten Elektrodenherstellung möglich

Contact person