News (Last 12 months)

New Landing Page for Nachhaltige Werkstofftechnik Degree Programm

A new landing page has been launched for the new Sustainable Materials Engineering degree program!

This course is all about increasing sustainability in the field of materials, with the following specialization options:

- Circular Metallurgy

- Sustainable Materials Manufacturing

- Materials and Processes for Life

- Data-Driven Materials Engineering for Sustainability

In Circular Metallurgy, the IME will present exciting recycling solutions for electric cars. From electronics to magnets to batteries, we will show how complex end-of-life material flows can be processed into reusable raw materials.

Access the link directly here: https://nwt.rwth-aachen.de/

Alumna Christin Stallmeister winning the Prize of the Stifterverband Metalle

Congratulations to our alumna Christin Stallmeister on receiving the Prize of the Stifterverband Metalle for her outstanding dissertation titled:

“Thermische Vorbehandlung und frühzeitige Lithiumrückgewinnung im Kontext pyrometallurgischer NMC-Lithium-Ionen-Batterie-Recyclingrouten.”

This prize is presented by the Stiftervereinigung Metalle, which recognizes exceptional scientific achievements in the field of metallurgy and supports promising young researchers under the age of 35.

The award was conferred during the 2025 European Metallurgical Conference (EMC).

We are immensely proud of Christin’s accomplishments and warmly congratulate her on this well-deserved honor!

IME at European Metallurgical Conference 2025

The IME team participated in the European Metallurgical Conference (EMC) 2025, held in Hamburg. Since 2001, IME has taken part in every occurrence of this biennial conference, contributing more than one hundred scientific papers to date.

The event provided an excellent platform to present and discuss our research with an international audience. A total of 15 scientific assistants from IME delivered a broad range of presentations and posters, highlighting the diversity of our research activities and once again underscoring our guiding principle: “From Nano to Mega, Metallurgy in All Dimensions.”

Beyond the technical program, our colleagues also had the opportunity to explore Germany’s second-largest city and strengthen team spirit through shared experiences.

If you are interested in any of the conference contributions, please visit our website.

Huge milestone: the new Electric Arc Furnace goes into operation

After a year of dedicated planning, engineering, and teamwork, we’re proud to announce the successful startup of our new large electric arc furnace! This 700 kVA AC furnace, equipped with three electrodes and a 350-liter capacity, marks a major step forward for our research capabilities. It’s a perfect embodiment of our institute’s motto: “From nano to mega – metallurgy in all dimensions.”

With this system, we can now scale our experiments seamlessly from laboratory to pilot scale.

As its name suggests, the EAF runs fully electrically — making it a vital tool for driving forward carbon-free metallurgy and sustainable metal processing.

A huge thank you to everyone who brought this project to life:

- Our scientific assistants: Dorothea Schneider, Fiona Pickart, Florian Wegmann, Joao Pedro Weiss

- Our plant technicians: Christopher Wels, Ali Sahin, Simon Stanetzky, Sergen Serin

- Our workshop team: Tobias Held, David Langohr, David Palmen, Fabian Böhm, Liam Dix, Paul Pleyers, Till Ritzerfeld And the constructor: Viktor Hügel

Your commitment and craftsmanship made this achievement possible!

MINT-EC Camp “Sustainability in Resource Engineering”

On May 15th, we hosted the MINT-EC Camp “Sustainability in Resource Engineering” for high school students.

Over the course of a week, they explored how raw materials are sourced and recycled, using the example of a smartphone, through hands-on workshops and inspiring lectures at the institutes of the Division of Materials Science and Engineering and the Division of Mineral Resources and Raw Materials Engineering.

At IME, they dove into: hydrometallurgical recycling of smartphone components; vacuum induction melting of aluminium; and electric arc furnace melting of stainless steel.

We are glad to host and show the green metallurgy world to the younger generations, and are very happy that they had great fun at our institute!

IME at Berliner Konferenz für Metallkreisläufe 2025

At the beginning of April, an IME delegation had the opportunity to participate in the Berliner Konferenz für Metallkreisläufe 2025.

We were proud to contribute two posters showcasing our recent work on the hydrometallurgical recovery of metals from black mass—a critical intermediate product in the recycling of lithium-ion batteries. Additionally, we presented our latest findings on the potential of thermal conditioning in enhancing the efficiency and selectivity of metal recycling processes.

Beyond the technical exchange, the conference offered an excellent platform to engage with a diverse range of professionals. We connected with many inspiring individuals, exchanged ideas, and discussed both the challenges and opportunities shaping the future of circular metals processes.

We are grateful for the insightful discussions, and we’re already looking forward to participating again next year!

Blockguss Forum 2025

At the end of March, the Blockguss Forum 2025 was hosted by IME RWTH Aachen in collaboration with MAGMA Aachen.

It was a two-day event filled with meetings, inspiring exchanges, and the opportunity to connect with many interesting individuals from various fields in industry and academia.

The event brought together experts from the remelting, ingot casting and refractory sectors.

Kick-off meeting Circular Electronics PhD program

On April 7, 2025, the official kick-off for the German-Indonesian PhD program “Circular Electronics” took place at the SuperC of RWTH Aachen University. In this program, RWTH institutes are working together with partner universities from Indonesia to develop innovative solutions for the recycling of electronic waste and to promote sustainable circular approaches.

A total of 15 doctoral students are planned for the doctoral program in Aachen. The research projects cover a broad spectrum: from the mechanical pre-treatment of electronic waste to new technologies for plastics recycling and the economic and social aspects of the circular economy.

As part of the kick-off meeting, the first PhD students presented their projects and reported on their experiences at RWTH. It became clear how important close interdisciplinary cooperation and integration into local academic life are.

With the PhD program, we are focusing on long-term cooperation, strengthening scientific exchange between Germany and Indonesia and making an active contribution to a more sustainable future.

New research project at IME: Recycling of Hydride Storage and Sorption Materials for Sustainable Hydrogen Storage

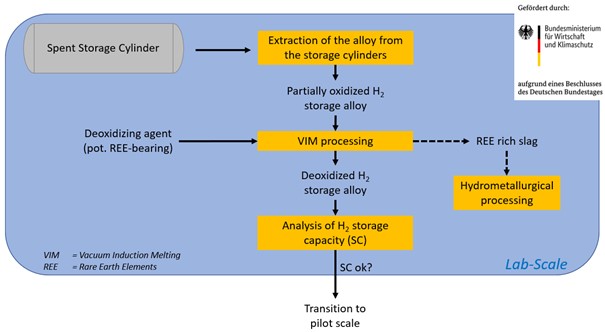

At IME, a new project funded by the BMWK is currently being carried out. The RISE project (Recycling of Hydride Storage and Sorption Materials for Sustainable Hydrogen Storage) is being conducted in collaboration with ThyssenKrupp Marine Systems, Fraunhofer IFAM, and GfE. The name already indicates that it concerns the recycling of retired hydrogen storage alloys. The focus of the investigations is on manganese-titanium-based alloys. These storage alloys were developed and brought to market maturity at the end of the last century, so they have been in use in specialized vehicles for several decades. For technical reasons, however, the service life of these storages is limited. While approaches to give these storages a second life are promising, there remains a necessity to ultimately develop and implement strategies for recycling.

During use, the storage alloy is housed in steel cylinders. During filling and emptying with hydrogen, the alloy undergoes expansion and contraction. Over its entire lifecycle, this leads to the pulverization of the alloy. The extremely high reactive surface area resulting from this causes oxidation of the alloy upon opening the cylinder to be unavoidable so far.

The aim of IME within the framework of this research project is to remelt the partially oxidized material in a vacuum induction furnace with the addition of deoxidizing agents. The challenge lies in developing a suitable setup that can withstand both the thermochemically aggressive melt and the deoxidizing agent. Subsequently, the actual recycling process or procedure will be designed. Additionally, it is being considered to hydrometallurgically process any slag containing rare earth elements that may arise during the process.

The melting processes will initially take place on a laboratory scale. After successful setup and process development, implementation will occur on a pilot and industrial scale.

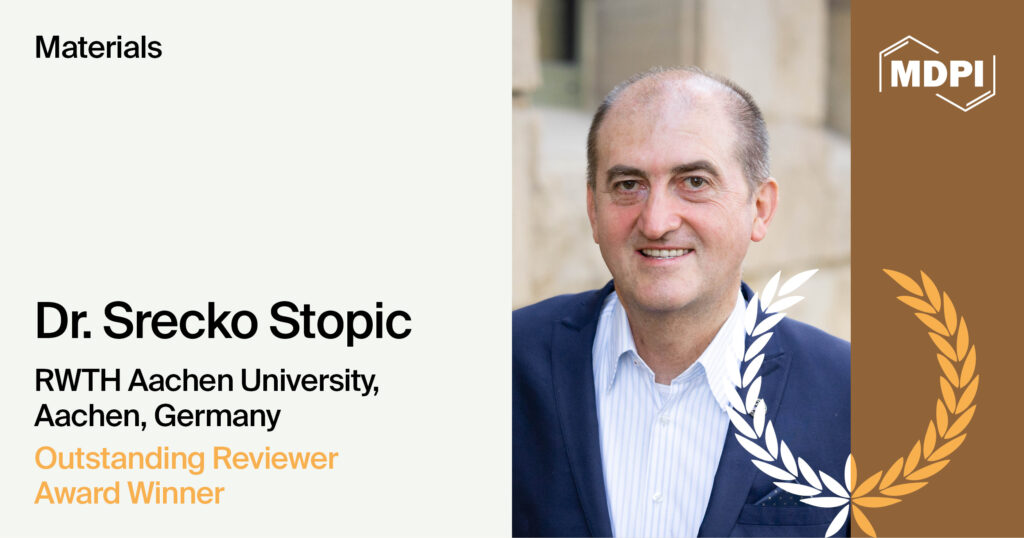

Dr. Srećko Stopić Honored Once Again with the Outstanding Reviewer Award

Congratulations to our colleague Dr. Srećko Stopić on receiving the Outstanding Reviewer Award once again! Following previous recognitions for his exceptional reviewing contributions to the journals Metals (2020) and Crystals (2023), he has now also been honored for his work with Materials (2024) – all published by the MDPI publishing house in Switzerland.

With this award, MDPI recognizes particularly dedicated reviewers who stand out through their thorough, reliable, and timely evaluations. Dr. Stopić is active not only as a reviewer but also as an editor and co-author.

For over 25 years, he has played a key role in shaping research at the IME and has supported numerous colleagues and students throughout the years. At the institute, he is known not only for his commitment but also for his extensive international network: from research collaborations with scientists in Côte d’Ivoire, to environmental projects tackling hazardous red mud in Bosnia, all the way to academic exchange programs with his home country of Serbia. Throughout his scientific career, he has published over 250 works, including four academic books.

We warmly congratulate Dr. Srećko Stopić on this well-deserved award and thank him for his many years of valuable contributions to the institute!

A press release has also been published on the official RWTH website. It can be accessed via the following link:

Kick-Off-Meeting ProMotion

Recently, together with our partners from Gebrüder Lödige Maschinenbau GmbH and the Öko-Institut e.V., we held the kick-off meeting for the ProMotion project at IME. In this project, we are jointly developing an innovative prototype reactor featuring a novel Ploughshare® mixer to improve the recycling of lithium-ion batteries and make the process more efficient and sustainable. The aim of the project is to significantly optimize the recycling process and thereby increase the recovery rates of critical raw materials such as lithium, as well as other valuable metal-containing compounds. As battery waste is expected to rise sharply in the coming years, finding better recycling solutions is more important than ever. The targeted process step usually follows the deep discharge, disassembly, and mechanical shredding of the battery cells. The focus is on thermal pre-treatment, which removes organic components and simultaneously generates soluble lithium compounds that can later be more easily separated. This pre-treatment also has a positive effect on subsequent hydrometallurgical processes—particularly due to improved wettability and a finer particle structure of the black mass. The new process aims to recover as many valuable raw materials as possible—such as lithium, nickel, and cobalt—while also significantly reducing environmental impact.

Kickoff Meeting second funding period of DFG project

The kickoff meeting for the second funding period of our DFG project priority program “Engineered Artificial Minerals” (EnAM) was conducted in Fulda. The event commenced with a welcome address by Prof. Peuker (MTVAT TU Freiberg), followed by presentations from each project team. These teams provided a summary of their accomplishments during the first funding period and outlined their objectives for the upcoming phase. In this second funding period, the primary focus of the central project is on the generation of slag from model systems that can yield sufficient slag material to support projects involved in subsequent processing steps. This central initiative will also entail the development and provision of 3D geo-metallurgical characterizations of the slags, along with supporting other projects through geo-metallurgical data. Within the project B8, which IME coordinates, we are engineering tantalum-rich mineral phases derived from recycling slags associated with waste electrical and electronic equipment (WEEE) through fluxes modification, controlled cooling and segregation. During this second phase of funding, we aim to generalize our investigations and process models and consider the applicability of their correlations to more than one slag system.

Colloquium of University Professor Candidates for IME

We are pleased to announce the colloquiums aimed at selecting a new university professor (W2) with Tenure Track for our IME Process Metallurgy and Metal Recycling. The new professorship will work alongside Professor Friedrich until his retirement at IME, focusing on battery and electronics waste recycling. Once the Tenure Track phase is completed, full leadership of the institute will be transferred. This event will provide candidates with the opportunity to present their research and teaching concepts.

For detailed information regarding the colloquium, including specific dates, times, and candidate profiles, please refer to the attached announcement. We invite faculty members, students, and all interested parties to attend this important event.

PDF file: Ankündigung Announcement_1738857989.pdf

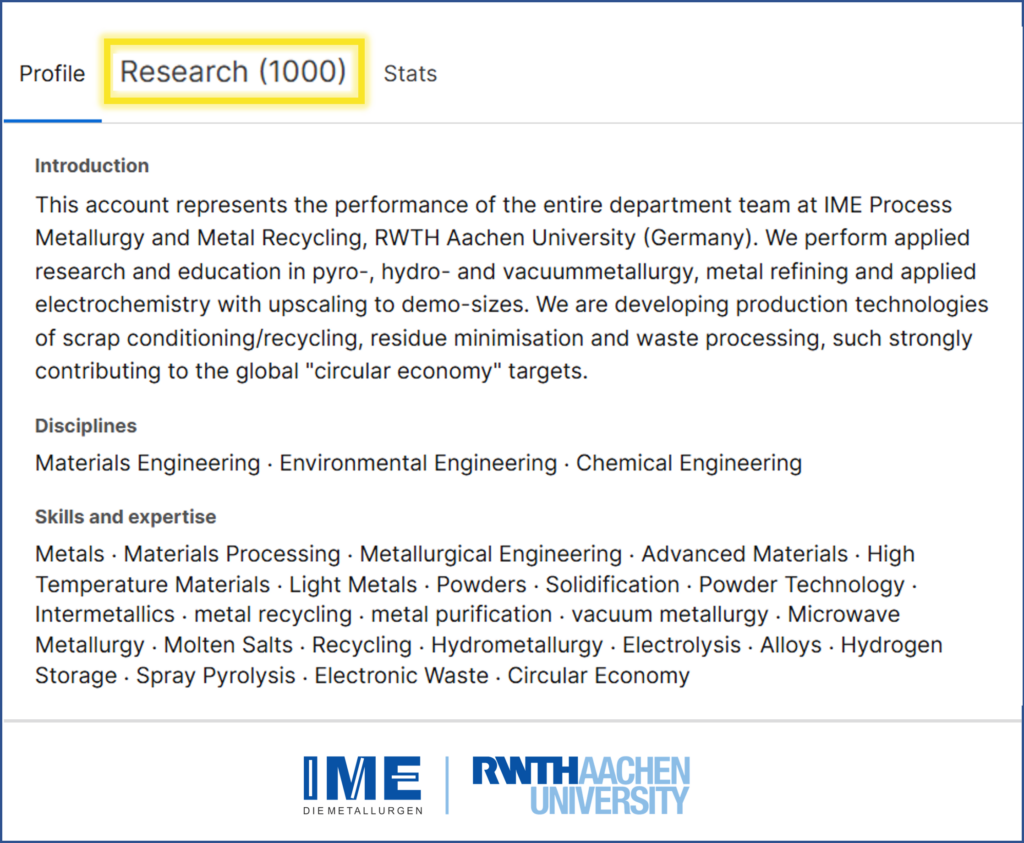

Milestone: 1,000 Research Contributions from IME in the Last 25 Years

IME is proud to announce that we have recently reached the significant milestone of 1,000 research contributions over the past 25 years! This achievement reflects the dedication, creativity, and collaborative efforts of our researchers, students, technicians, and administrative staff. Over the past quarter century, our work has spanned diverse aspects of metallurgy: from nanoparticles to battery recycling, from slag design to hydrogen applications and metal purification, we remain attentive to emerging challenges and continuously foster a more sustainable and green future of metallurgy. Whether in pyrometallurgy, hydrometallurgy, electrochemistry, or beyond, our institution strives to advance knowledge and develop innovative solutions. The scope of these 1,000 publications underscores our collective impact and includes (for example):

- 430 Research Articles

- 251 Conference Papers

- 185 Presentations

- 82 Posters

- 18 Patents

Link: www.researchgate.net/profile/Bernd-Friedrich-2

Montan University Leoben awards honorary doctorate to Professor Bernd Friedrich

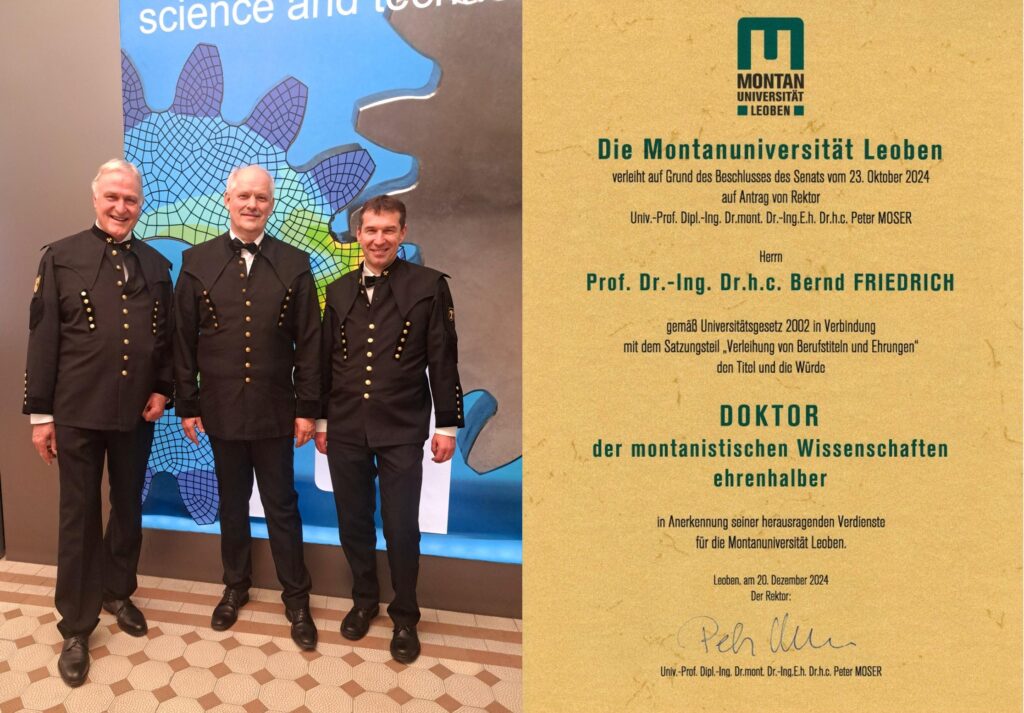

Shortly before Christmas, the Montanuniversität Leoben in Austria awarded Professor Bernd Friedrich an honorary doctorate. In the left picture, you can see Professor Peter Moser, Rector of the Montanuniversität Leoben, and Professor Helmut Antrekowitsch, Vice Rector for Research and Sustainability, on the left and right side of Prof. Bernd Friedrich. With this distinction, the Austrian university recognizes his significant scientific contributions as well as his longstanding commitment to fostering young researchers.

25 years ago, Professor Friedrich revitalized the collaboration with the Lehrstuhl für Nichteisenmetallurgie (Chair of Non-Ferrous Metallurgy) at the Montanuniversität Leoben. Together with colleagues from Leoben, he initiated the annual Young Researcher Workshop for Non-Ferrous Metallurgists, also known as the “Aachen-Leoben Workshop.” This format has fostered a close partnership and intensive scientific exchange.

The collaboration extends far beyond the workshop: in addition to promoting academic exchange among doctoral candidates, the two chairs of non-ferrous metallurgy work closely together in EU projects and teaching activities. Together, they address current challenges, such as enhancing the attractiveness of study programs, fostering young talent, and securing the economic sustainability of the field.

We extend our heartfelt congratulations to Professor Friedrich on this honor! A special thanks goes to all those who have shaped and sustained this close collaboration. We look forward to a continued successful partnership between the two chairs of non-ferrous metallurgy.

Details of the Honorary Doctorate:

The Montanuniversität Leoben grants, based on the decision of the Senate from October 23, 2024, on the recommendation of the Rector, Univ.-Prof. Dipl.-Ing. Dr.mont. Dr.-Ing.E.h. Dr.h.c. Peter Moser, to Prof. Dr.-Ing. Dr.h.c. Bernd Friedrich, pursuant to the University Act of 2002 in conjunction with the statute section “Granting of Academic Titles and Honors,” the title and dignity of Doctor of Montanistic Sciences honoris causa, in recognition of his outstanding merits for the Montanuniversität Leoben. Leoben, December 20, 2024 The Rector: Univ.-Prof. Dipl.-Ing. Dr.mont. Dr.-Ing.E.h. Dr.h.c. Peter Moser

This news has also been featured in the Montanuniversität Leoben newsletter, available at the following link:

Link: www.unileoben.ac.at/news/akademische-feier-11/

New Special Issue on the Topic Battery Recycling edited by Professor Bernd Friedrich

This Special Issue brings together 24 insightful articles, offering a deep dive into the latest advancements in battery recycling. The collection explores the essential conditions for recycling efficiency, covering various battery types and processes step by step. Key topics include:

- Innovative Sorting Methods: Studies highlight the use of air classifiers to separate battery foils and advanced sensors for sorting materials by type, boosting the precision of recycling processes.

- Thermal Pretreatment: Thermal pretreatment on materials like NMC 622 black mass emerges as a critical step in removing organic compounds and breaking down materials. This enables easier and more effective recovery of valuable components. Researchers also explore techniques such as sulfuric roasting for LCO-rich black mass and methods for safe lithium recovery from LiS cells.

- Hydrometallurgical Advances: After pretreatment, hydrometallurgical processes recover valuable elements like lithium, cobalt, and nickel. Studies explore eco-friendly options, such as organic acids (e.g., gluconic and acetic acids), to enhance efficiency while minimizing environmental impact.

Link: www.mdpi.com/books/reprint/10197-new-science-based-concepts-for-increased-efficiency-in-battery-recycling-2023

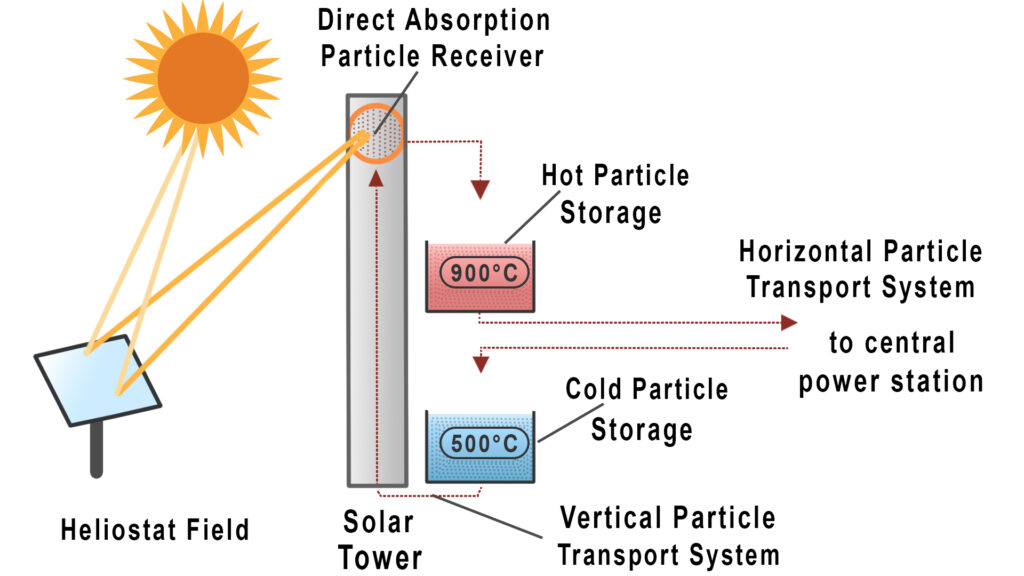

New research project at IME: Conversion of metallurgical residues into materials for solar power plants

A new DFG research project has been launched at IME in which a scientific methodology is being developed and evaluated that enables the targeted synthesis of technical secondary raw materials from metallurgical residues and fine ceramics to be recycled as additives. As an application case, fayalitic by-products and ceramic processing residues are to be investigated as secondary resources for the synthesis of ceramic particles with specific thermal, optical and structural properties. The synthesized ceramic particles will be used as heat transfer and storage media in solar power plants in the future. The properties will be compared with those of ceramic particles produced from unmodified raw materials according to the state of the art in order to evaluate the new method. In addition, thermodynamic modelling and experimental results will be combined to validate the hypotheses of this research and to develop a generalized, integrated model workflow for the conversion of metallurgical by-products into ceramic particles with application-specific properties.

Link: www.metallurgie.rwth-aachen.de/#/research/project/176

New podcast about aluminium recycling

Prof. Dr. Ing. Friedrich was able to record a new podcast with Mr. Voss on the topic of aluminium recycling. The aluminium recycling industry is currently confronted with a huge amount of new aluminium scrap, which is often contaminated with plastics, unwanted metals or ceramics. This creates a high demand for suitable and economically viable refining options. As a result, new questions arise in research, such as the approach of universities like RWTH Aachen University in this area, the control of relevant impurities as well as existing industrial practices and promising future technologies. There is also the question of the need for multiple processes or a single solution for all contaminants. We would also like to thank the AMAP (Aachen Center for Metal and Alloy Processing) for their support in realising this podcast. The complete podcast is available at the following link.

Link: creators.spotify.com/pod/show/simon-vo/episodes/47-Aluminum-Recycling-for-a-Circular-Economy—Prof–Bernd-Friedrich-e2r3udt

100 Years of Otto-Junker: Support for Innovative Research Projects

We would like to congratulate Otto-Junker on its 100th anniversary. As a world-leading provider of industrial furnace systems for melting, heat treatment, and recycling, Otto-Junker has been supporting educational and research institutions for many years through its foundation. The foundation supports numerous research projects, including at the IME, which not only enable scientific progress but also sustainable solutions to current challenges. As part of a research project funded by the Otto Junker Foundation, a new plant for the pyrolysis of battery cells and modules was successfully put into operation at the IME recently. This plant is used to investigate the upscaling of battery pyrolysis for both cells and entire modules. The findings on battery pyrolysis gained on a laboratory scale can now be transferred to large numbers of cells and entire modules for further research. We look forward to continuing our successful collaboration with Otto Junker and the Otto Junker Foundation and wish Otto Junker every success in the future.

Link: www.otto-junker.com/de/unternehmen/100-jahre-otto-junker/