About Us

The IME Metallurgical Process Engineering and Metal Recycling – Institute and Chair of RWTH Aachen University (short form: IME) at RWTH Aachen University is a teaching and research institute in the field of metallurgical extraction, recycling, refining and synthesis of non-ferrous metals and alloys. Current research focuses strongly on activities related to the circular economy. For example, ongoing research projects are developing metallurgical processes that enable sustainable management of metal-bearing waste and residual materials and thus strengthen the supply of raw materials in the European economic area. The IME is integrated in the department for “Materials Science and Materials Engineering” (MuW) of the Faculty of Georesources and Materials Engineering.

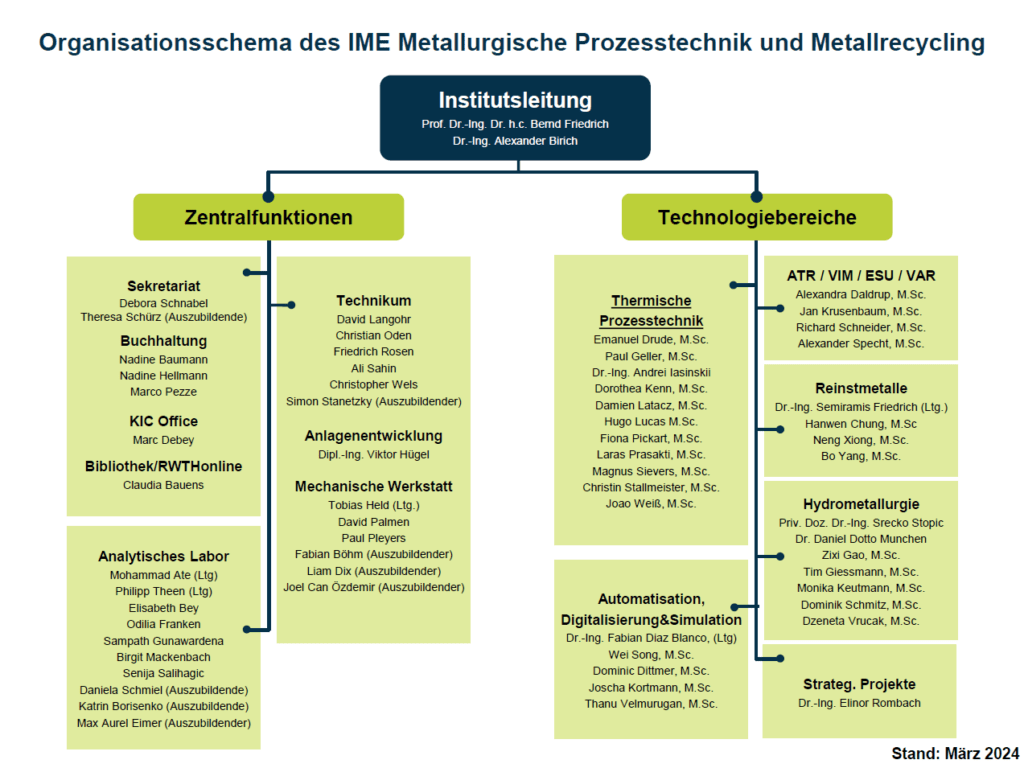

Our Organization

Research Areas

The traditional focus of recycling metallurgy as a contribution to the circular economy is based on the use of TBRCs or electric arc furnaces, where reprocessed battery components, electronic scrap, used catalytic converters but also industrial residues such as dusts, sludges or slags are processed.

In the field of materials process technology, inert gas/vacuum metallurgy with the processes of inductive melting, electroslag remelting and vacuum arc melting occupies a large space, and is supplemented by many refining processes for the production of very pure metals (zone melting, fractional crystallization, distillation and purge gas treatment).

The third research platform consists of laboratories for fundamental research, in which thermochemically modeled equilibria between metal and slag are experimentally validated, the kinetics of metallurgical reactions are determined, and properties of molten phases (e.g. viscosity, density, surface tension, conductivity) are determined.

In 2017, the IME succeeded in protecting the trademark “Green Metallurgy” throughout Europe. Metallurgical concepts and processes that are based on the idea of environmentally friendly, sustainable, zero-waste and low-emission metallurgy are identified with this name/logo.

Awards and Cooperations

The IME has received various awards for its scientific achievements in the field of non-ferrous metallurgy. For example, the institute was awarded the German Raw Material Efficiency Prize 2012 by the German Federal Ministry for Economic Affairs and Energy for the process developed with the company Accurec Recycling GmbH for the recovery of raw materials from electronic waste, in particular from batteries. In addition, the IME was the winner of the world’s most highly endowed metallurgical Kaiserpfalz Prize of the Wirtschaftsvereinigung Metalle in 2008, 2012 and 2016. Thematically, battery recycling as well as nanotechnology and titanium metallurgy were backgrounds for this honor.

The IME was actively involved in the foundation of the European research network EIT RawMaterials and represents the interests of the RWTH as a core partner (rectorate representative). RWTH’s participation in EIT RawMaterials strengthens its presence in the European region, provides information on developments in the raw materials industry and enables the promotion of teaching and innovation projects. As one of six institutes at RWTH Aachen University, the IME is a founding member of the AMAP (Advanced Metals and Processes) open innovation research cluster, in which joint precompetitive research projects are carried out to strengthen aluminum as a material. This research cluster also includes 14 industrial companies.

Intensive cooperation with the National Technical University of Donetsk in Ukraine has resulted in a leading position in the field of titanium metallurgy, which was honored, among other things, with the award of an honorary doctorate to Prof. Bernd Friedrich.[11] The IME maintains further strategic partnerships with the Technical University of Istanbul (hydrometallurgy), the University of Maribor (nanopowders), the National Technical University of Athens (industrial residues) as well as with the University of Belgrade (electrochemistry).

Courses Offer

- The structural change that has taken place in the metal industry in recent years has also had a serious impact on engineering qualifications. Small and medium-sized enterprises (SMEs) in particular increasingly demanded interdisciplinary skills. Consequently, an engineer has to be trained who is able to develop and optimize metallurgical processes as well as metal alloys by combining profound knowledge in metallurgy, plant engineering and computer science.

- The practically oriented study of non-ferrous metallurgy in the department “Materials Science and Engineering” is designed to meet these requirements. In doing so, the ability to develop processes for the production of innovative metallic materials as well as for their recycling should be a major focus. The courses offered by the IME are primarily aimed at students of materials engineering, as well as industrial engineering (focus on materials and process engineering) and environmental engineering (focus on raw materials engineering). These are trained at RWTH Aachen University in a 6-semester bachelor’s/4-semester master’s program or in a 4-semester English-language postgraduate program leading to a “Master in Metallurgical Engineering”.

- In all three courses of study, the specializations Thermal Extraction Processes, Thermal Refining Processes and Hydrometallurgy are offered. Furthermore, the elective courses “Resource Efficiency in Metal Recycling”, “Metallurgy and Properties of Al Melts”, “Planning and Economics of Metallurgical Plants” and “The Value Chain of Rare Earths (SE)- Extraction and Recycling” complete the institute’s curriculum.