Research » Nanopowder Synthesis

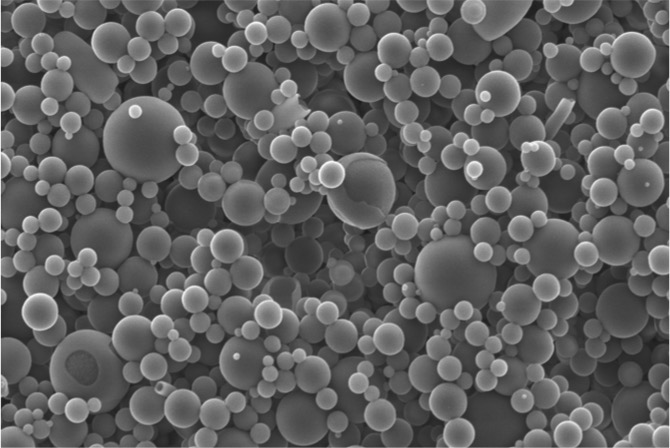

Nanotechnology belongs to the key innovative technologies for powder production. Ultrasonic spray pyrolysis USP is a versatile method for the formation of nanosized particles of metals, oxides and composites. Our work deals with nanoparticles of Ag, Cu and Au formed by ultrasonic spray pyrolysis using the horizontal and vertical reactor. Furthermore, a direct synthesis of Ru-TiO2 and RuO2-TiO2 nanoparticles with the core and shell structure was investigated. Molar fractions of precursors, solvent type, and the process temperature play the crucial roles in the formation of core and shell structures. Moreover, the influence of the reaction parameters (temperature, residence time, concentration of solution and ultrasonic frequency) on the morphological characteristics of the prepared nanoparticles was studied. A decrease in the solution concentration decreases the final nanoparticle size. An increase in temperature from 150°C to 1000°C leads from an irregular form to a more spherical one. Subsequently, a model of metallic nanoparticle formation from an aerosol droplet could be proposed. Using USP, ideal spherical metallic particles were obtained at temperatures above the melting point. A scanning mobility particle sizer was used for the on-line determination of nanoparticle size distribution. The collection of nanosized particles was performed in an electrostatic field. Nanotechnology belongs to the key innovative technologies for powder production. Ultrasonic spray pyrolysis USP is a versatile method for the formation of nanosized particles of metals, oxides and composites. Our work deals with nanoparticles of Ag, Cu and Au formed by ultrasonic spray pyrolysis using the horizontal and vertical reactor. Furthermore, a direct synthesis of Ru-TiO2 and RuO2-TiO2 nanoparticles with the core and shell structure was investigated. Molar fractions of precursors, solvent type, and the process temperature play the crucial roles in the formation of core and shell structures. Moreover, the influence of the reaction parameters (temperature, residence time, concentration of solution and ultrasonic frequency) on the morphological characteristics of the prepared nanoparticles was studied. A decrease in the solution concentration decreases the final nanoparticle size. An increase in temperature from 150°C to 1000°C leads from an irregular form to a more spherical one. Subsequently, a model of metallic nanoparticle formation from an aerosol droplet could be proposed. Using USP, ideal spherical metallic particles were obtained at temperatures above the melting point. A scanning mobility particle sizer was used for the on-line determination of nanoparticle size distribution. The collection of nanosized particles was performed in an electrostatic field.

Project List

- Artificial Neural Network modelling of silver nanoparticle formation after thermal decomposition of an aerosol

- Designing of nanoparticle morphology in aerosol synthesis

- Electromechanical components with new nanoparticle-modified precious metal surfaces – NanoGold

- “LiVe” lithium battery composite structures

- Process design of ultrasonic spray pyrolysis synthesis of RuO2/TiO2 nanoparticles for catalytic application

- Synthesis of Gold nanoparticles for dental/medical application

- Designing of nanoparticle morphology in aerosol synthesis

- Aerosol Synthesis of Nanoscaled Particles for Catalytic Application

Publications

| Year | Publications |

|---|---|

| 2025 |

congress or congress paper

HydroMetEC: International seminar 16 January 2025

|

| 2025 |

article in scientific journal

Recovery of Titanium and Aluminum from SecondaryWaste Solutions via Ultrasonic Spray Pyrolysis. Metals 2025, 15, 701. https://doi.org/ 10.3390/met15070701

|

| 2025 |

congress or congress paper

Symposium LYO Gold, Ljubljana

|

| 2024 |

poster

Z1 – Central Project, May 2024

|

| 2024 |

article in scientific journal

Materials 2024, 17(19), 4779; https://doi.org/10.3390/ma17194779

|

| 2024 |

article in scientific journal

ChemEngineering 2024, 8(3), 63; https://doi.org/10.3390/chemengineering8030063

|

| 2023 |

article in scientific journal

Colloids and Surfaces A: Physicochemical and Engineering Aspects; https://doi.org/10.1016/j.colsurfa.2023.132837

|

| 2023 |

article in scientific journal

Metals 2023, 13(10), 1686; https://doi.org/10.3390/met13101686

|

| 2023 |

article in scientific journal

Metals 2023, 13, 280; https://doi.org/10.3390/met13020280

|

| 2022 |

article in scientific journal

Metals 2022, 12, 1802

|