News

New research project at IME: Thermal treatment of blackmass through rotary kiln microwave technology

General Assembly and Alumni Gathering 2025 of the Freunde des IME Association

Prof. Bernd Friedrich at Expert Forum Green & Circular Metals SIGN Launch

New research project at IME: Closed-Loop Recycling of Photovoltaic Modules

Newsletter

IME Aktuell 49

Topics of this edition:

- GLBO commissioning

- BMBF project ‘ProMotion’ with Gebr. Lödige GmbH

- Block Casting Forum 2025

Activities and Events

Category:

Information:

Date:

The World of Green Metallurgy®

The activity of the Institute IME Process Metallurgy and Metal Recycling (Professor Dr.-Ing Dr. h.c. Bernd Friedrich) consists of applied research and education/teaching in the fields of extractive metallurgy (pyrometallurgy and hydrometallurgy), metal refining and electrolysis, as well as recycling of metals and residues. IME-RWTH is also a leading institute in field of process design and optimization in terms of resources efficiencies with special focus on critical waste streams aiming to support the sustainability on Circular Economy. We are involved in production technologies of complex alloys under vacuum up to demo-scale and powder synthesis in nano-scale.

| Year | Publications |

|---|---|

| 2025 |

article in scientific journal

Resources, Conservation & Recycling 227 (2026) 108766

Ayesha Tasawar, Daniel Munchen, Alexander Birich, Rungsima Yeetsorn, Walter Sebastian Scheld, Waritnan Wanchan, Benjamin Butz, Bernd Friedrich

|

| 2025 |

article in scientific journal

Minerals 2026, 16, 47 https://doi.org/10.3390/min16010047

Soner Top, Mahmut Altiner, Huseyin Vapur, Sait Kursunoglu, Srecko Stopic

|

| 2026 |

article in scientific journal

Processes 2026, 14, 33 https://doi.org/10.3390/pr14010033

|

Electronic Scrap Recycling

The IME pursues the objective to use the high potential of WEEE as a resource for various metals by developing a sustainable metallurgical recycling process. The focal point is the recovery of base metals (copper, aluminum), precious metals (gold, silver, platinum and palladium) as well as critical elements (gallium, germanium and indium). Currently, five doctoral studies examine different approaches of hydro- and pyrometallurgical processes concerning their selectivity, efficiency and flexibility. These processes aim at the treatment of several waste streams (such as printed circuit boards, shredder dust or whole smartphones) to recover various valuable metals with minimal losses. By elaborating several single methods, a process concept will be developed, which enables the recovery of individual elements through a flexible combination of these methods, adapted to a given waste stream and particular requirements.

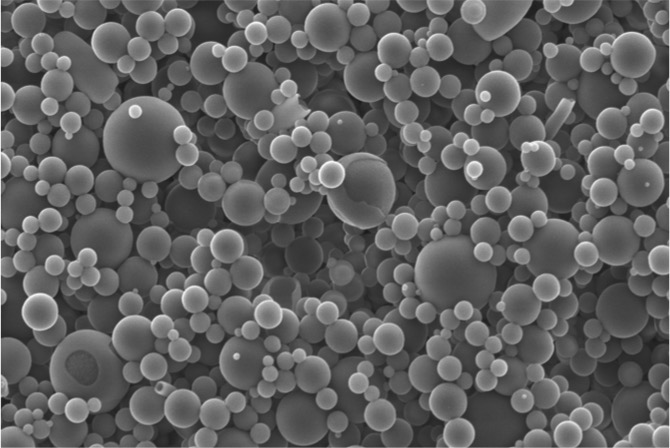

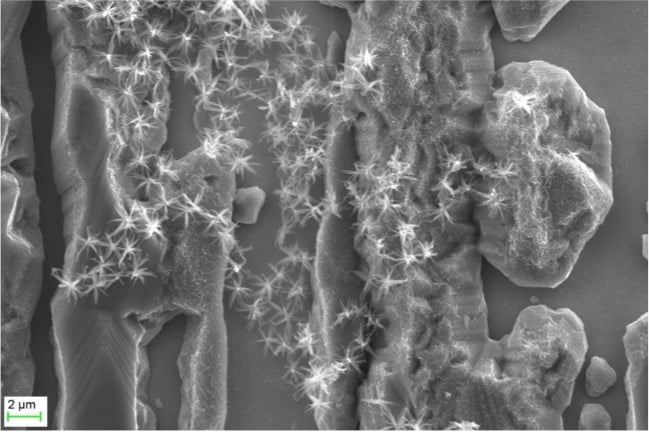

Nanopowder Synthesis

Nanotechnology belongs to the key innovative technologies for powder production. Ultrasonic spray pyrolysis USP is a versatile method for the formation of nanosized particles of metals, oxides and composites. Our work deals with nanoparticles of Ag, Cu and Au formed by ultrasonic spray pyrolysis using the horizontal and vertical reactor. Furthermore, a direct synthesis of Ru-TiO2 and RuO2-TiO2 nanoparticles with the core and shell structure was investigated. Molar fractions of precursors, solvent type, and the process temperature play the crucial roles in the formation of core and shell structures.

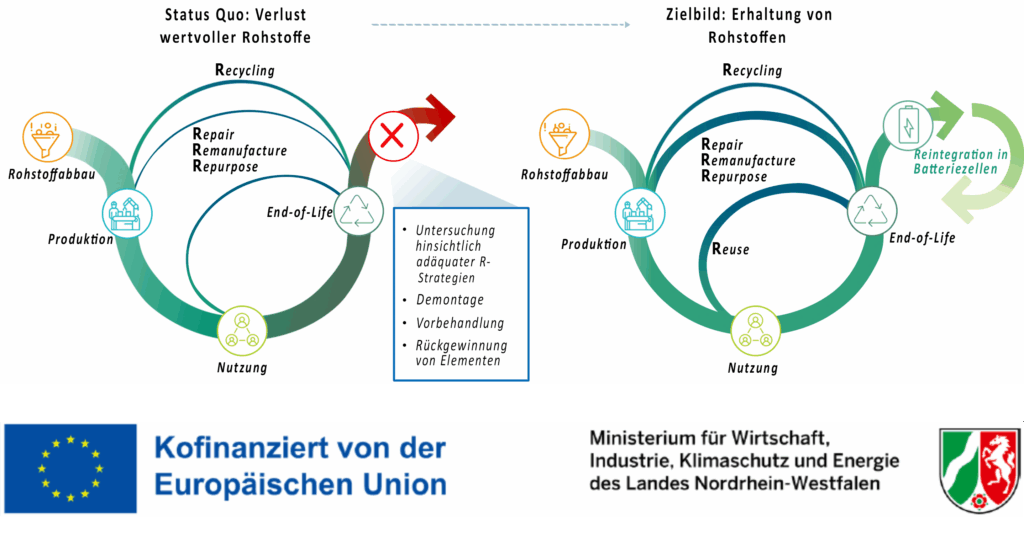

Circular Economy for Batteries

The IME represents the field of process metallurgy and metal recycling at RWTH Aachen University. Due to the growing public, political and industrial interest in battery recycling the IME has systematically developed optimal pyrometallurgical and hydrometallurgical recycling concepts for all standard battery systems in cooperation with industrial partners and also in terms of projects funded by the government. Some of these methods have already been implemented industrially and has been rated as BAT (Best Available Technology).

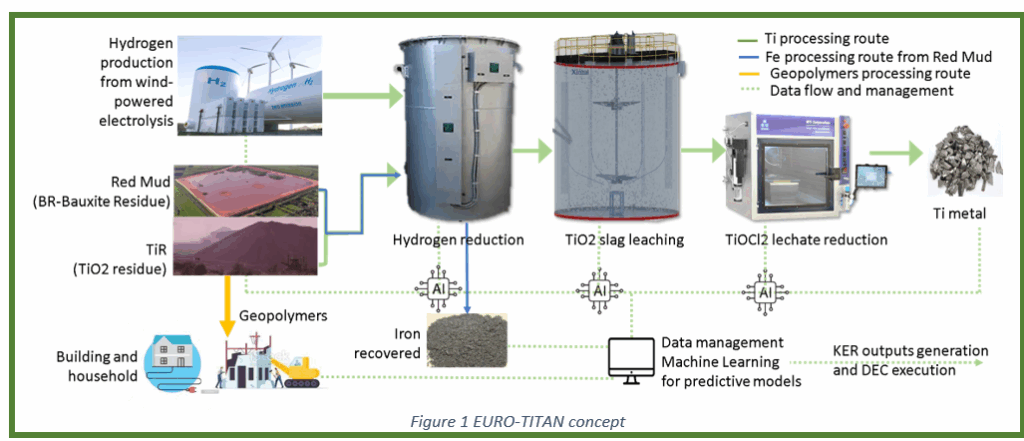

Titanium Metallurgy

Titanium is called the material of the future. This title results from the unique combination of properties such as good corrosion resistance, high strength and biocompatibility with low density. Due to these properties, titanium alloys are increasingly being used in areas such as aerospace, automotive, chemical or medical technology. Despite its relative commonness as the fourth most abundant element in the earth’s crust, titanium remains denied a wide industrial use. The reason for this is the high price of the metal, which results from the production costs. To reduce these and thus to allow the titanium the broad mass accessibility is a big challenge in research.

Technology Metals (Extraction and Recycling)

Critical metals are, by definition, metals that are of high economic importance and at the same time exhibit significant supply risks. Elements that are ascribed as especially critical are, for example, rare earth elements, platinum group metals, but also antimony and niobium. At IME, pyrometallurgical as well as hydrometallurgical processes for economic, efficient and environmentally friendly treatment and extraction of critical metals are investigated. The following list abstracts some of our current research topics in this field:

Aluminum Recycling and Melt Purification

The working group focuses on the recycling of aluminium scraps via under salt or salt-free processes. Top Blown Rotary Converter (TBRC) in lab and demo-scale is used to perform the experiments. Efficient coagulation during recycling is also studied by using different salt compositions. In addition, thermal treatment of organic containing materials is being investigated to find an optimum process which is a combination of pre-treatment and recycling. Moreover, the working group performs investigations about the melt cleanliness by using different removal and detection technologies to meet the high requirements of the product and material properties. Fundamental researches on particle behaviour in melts such as settling and agglomeration are also on-going to gain more knowledge about particles. Improvement of existing technologies and understanding of the mechanisms are main targets of the activities.

Waste Treatment and Primary Metallurgy

The primary production of metals is usually accompanied by by-product residues. These residue streams are a potential problem due to environmental concerns. Contained in these residues are valuable metals in lower grades than the primary production source. The IME is seeking means to exploit these vast secondary resources for value reclamation through development of innovative processes. The focus areas include and are not limited to the following: slag cleaning for recovery of precious metals, landfill mining to recover metals and plastics, red mud processing for recovery of high value metals such as Sc and Ga. Inertization of slags is another large research focus. Metallurgical slags can be modified so that they may be used e.g. as cement additives or as road building materials. This “zero-waste” approach contributes enormously to a sustainable metal production, which is actively propagated by IME in R&D projects and teaching.

Alloying Metallurgy

Alloying metallurgy is confronted with increasing complexity, as requirements of metallic high-tech materials rise with regard to composition, cleanliness and homogenity. In order to comply with strict tolerances, metallurgical vacuum processes are applied, which allow, for instance, melting of metals with high oxygen affinity, removal of dissolved gases or non-metallic inclusions as well as selective distillation of volatile metals. The available equipment at IME for these purposes comprises various vacuum induction furnaces, a pressure-slag-remelting unit and a vacuum arc furnace. Currently research on the following projects is conducted:

Pure Metals

The rapidly growing development and progress in the semiconductor, solar panel, photovoltaic and also the catalytic industry, has recently considerably increased the production and the number of applications of high-purity metals. In order to ensure the extremely low level of impurities (ppm or even ppb range), complex and highly controlled processes are required. The Pure Metals Group at IME focuses on alternative and cost-efficient methods, particularly based on the principle of fractional crystallization to produce high-purity metals such as Germanium, Indium, Antimony but also Aluminum, etc.

SeRoBatt – Secondary sources of critical raw materials for battery cell production – potentials, recovery, resynthesis

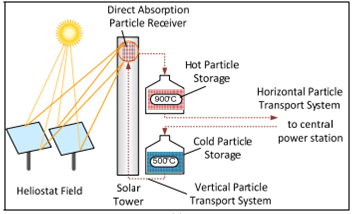

Solar

Short Circuits – Development of a small-scale processing route for the localised short-loop recycling of waste electronic circuit boards

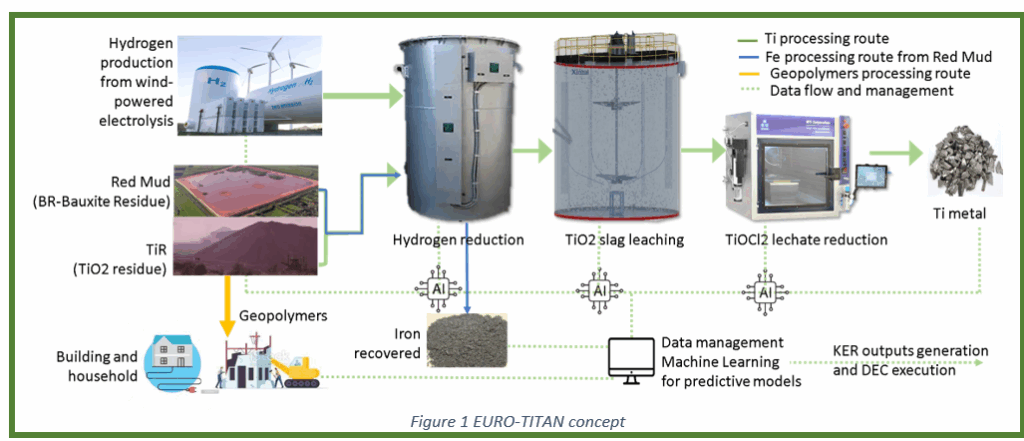

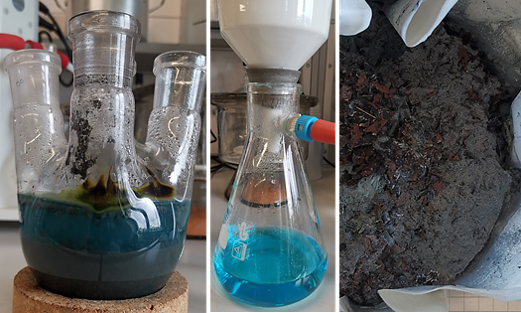

EURO-TITAN: Decarbonized Titanium Recovery from Aluminium and Titanium Production Residues

HEEERO – Hydrometallurgical Electrical and Electronic Equipment Recycling Optimization

EarLi: Extraction and purification of lithium hydroxide monohydrate from used electromobile Li-ion batteries for battery cell production

International Masters Programme in Energies & Green Hydrogen(IMP-EGH)

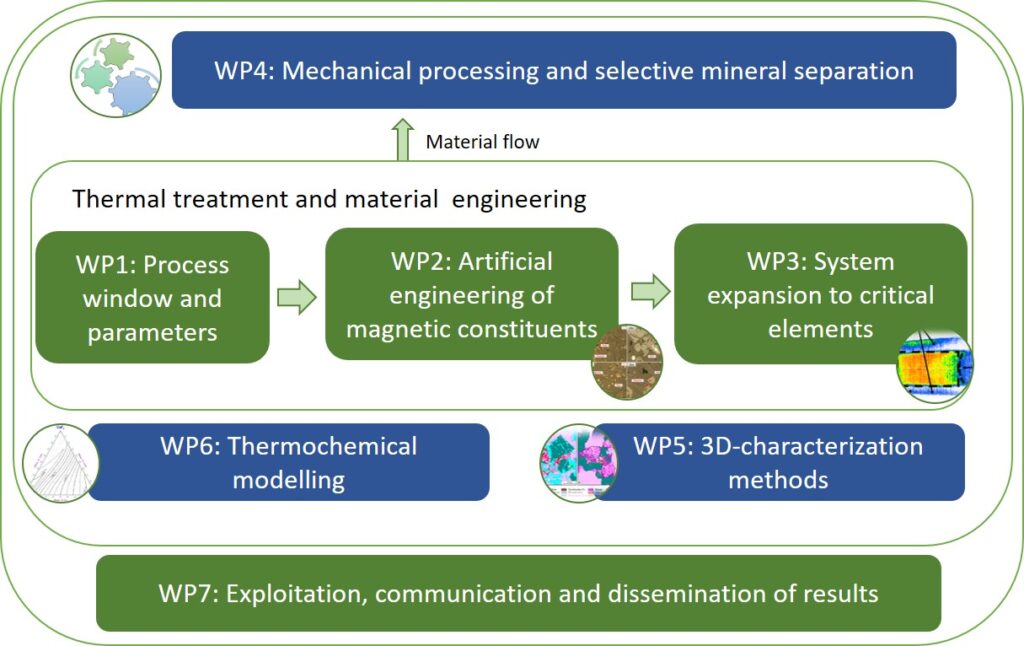

MeteoR – Mechanical-Thermochemical Process Combination for the Recycling of Fine Fractions from Waste Treatment Plants

PhöMixBeton – Process for the production of alkali-activated binders by melting mineral residues for an ecologically controlled mix design of concrete

HVBatCycle – HV-battery recycling and resynthesis processes for sustainable and functionally preserved material cycles

CO2-free aluminium production

CLIMA – Chemical-free lithium recovery from lithium-ion based spent batteries

Creation of an extraction concept for Te-metal through reduction and its purification up to the production of high-purity Tellurium

ProLiMo – Process development for lithium recovery from Li-ion batteries for tomorrow’s raw material security

Formation of Ta-rich magnetite phases in WEEE recycling slags through modification and controlled cooling

Central project – Slag synthesis, design and characterization

SMART – Application of Artificial Intelligence for wastewater treatment processes in the West Balkans countries

HARARE – Hydrogen as the reducing agent in the recovery of metals and minerals from metallurgical waste

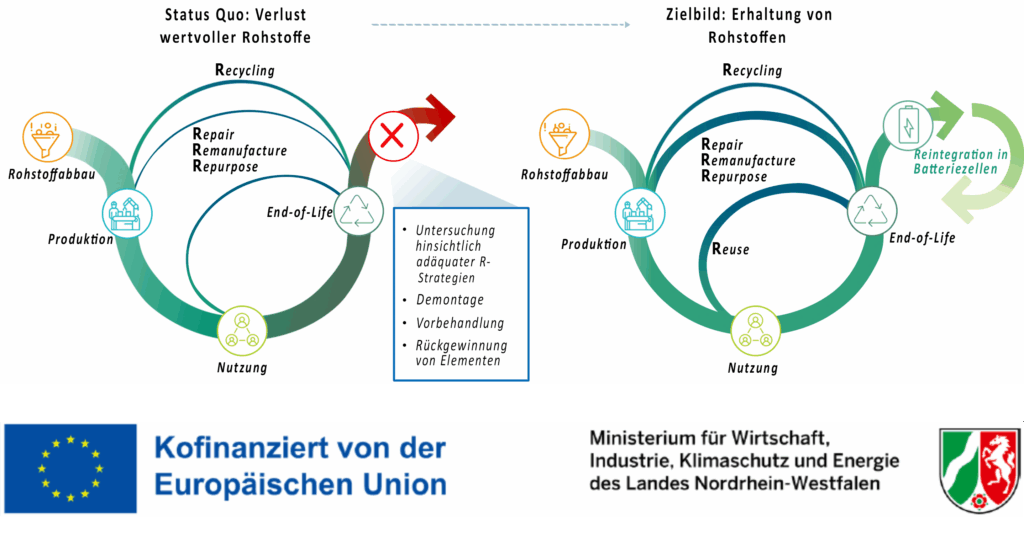

SeRoBatt – Secondary sources of critical raw materials for battery cell production – potentials, recovery, resynthesis

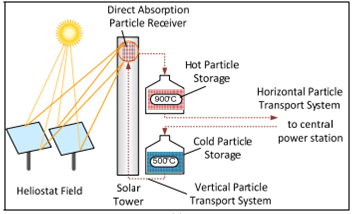

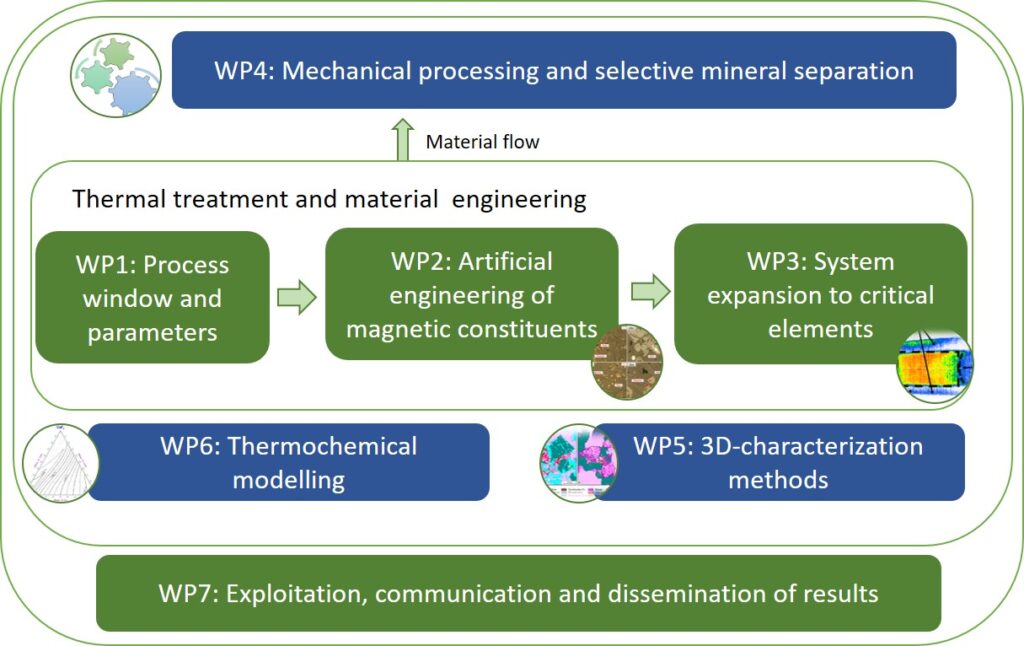

Solar

Short Circuits – Development of a small-scale processing route for the localised short-loop recycling of waste electronic circuit boards

EURO-TITAN: Decarbonized Titanium Recovery from Aluminium and Titanium Production Residues

HEEERO – Hydrometallurgical Electrical and Electronic Equipment Recycling Optimization

EarLi: Extraction and purification of lithium hydroxide monohydrate from used electromobile Li-ion batteries for battery cell production

International Masters Programme in Energies & Green Hydrogen(IMP-EGH)

MeteoR – Mechanical-Thermochemical Process Combination for the Recycling of Fine Fractions from Waste Treatment Plants

PhöMixBeton – Process for the production of alkali-activated binders by melting mineral residues for an ecologically controlled mix design of concrete

HVBatCycle – HV-battery recycling and resynthesis processes for sustainable and functionally preserved material cycles

CO2-free aluminium production

CLIMA – Chemical-free lithium recovery from lithium-ion based spent batteries

Creation of an extraction concept for Te-metal through reduction and its purification up to the production of high-purity Tellurium

ProLiMo – Process development for lithium recovery from Li-ion batteries for tomorrow’s raw material security

Formation of Ta-rich magnetite phases in WEEE recycling slags through modification and controlled cooling

Central project – Slag synthesis, design and characterization

SMART – Application of Artificial Intelligence for wastewater treatment processes in the West Balkans countries

HARARE – Hydrogen as the reducing agent in the recovery of metals and minerals from metallurgical waste